SEO Title: Leading SMD Mounting Supplier Offers High-Quality OEM Services

By:Admin

Subtitle: Unveiling Innovative Solutions and Unparalleled Quality to Address Industry Demands

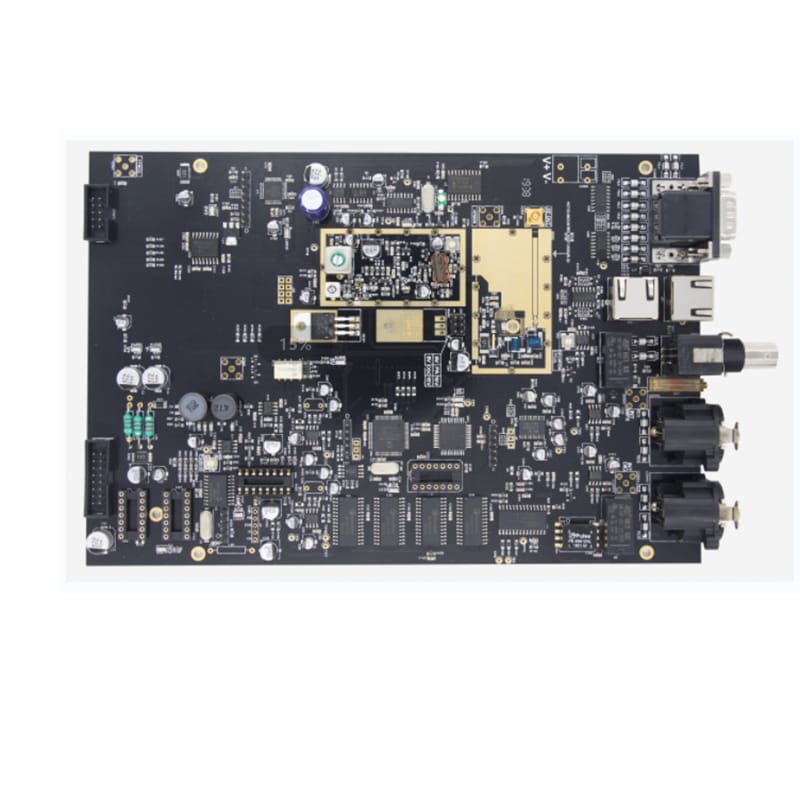

[City, Date] - Prominent SMD mounting supplier, renowned for its cutting-edge solutions and commitment to excellence, has recently undertaken a dynamic transformation to further enhance its services and customer experience. With an in-depth understanding of market demands and a passion for innovation, the company is well-positioned to revolutionize the SMD mounting industry.

Founded with a vision to redefine industry standards, this leading SMD mounting supplier has consistently contributed to the growth of global manufacturing by providing top-notch OEM solutions. Serving a wide range of industries such as automotive, telecommunications, aerospace, and consumer electronics, the company has earned an outstanding reputation for its unwavering commitment to quality and reliability.

Recognizing the need to adapt and evolve to remain at the forefront of the industry, the company has recently revamped its operations and made substantial investments in state-of-the-art equipment to ensure unmatched production capabilities. With this upgrade, the company is now capable of offering faster turnaround times, increased product customization options, and improved quality control measures.

One of the key aspects of the company's transformation lies in its cutting-edge manufacturing processes. By adopting advanced technology-smt/'>surface mount technology (SMT) and automated component placement techniques, the company has significantly improved its efficiency and productivity. This allows for the precise placement of SMD components on complex PCBs, ultimately leading to enhanced product performance and reliability.

Furthermore, the company has expanded its R&D division to focus on developing innovative solutions tailored to meet the evolving demands of the market. By investing in highly skilled engineers and leveraging the latest technological advancements, the company now offers a wide range of SMD components, including resistors, capacitors, diodes, and integrated circuits, catering to a diverse set of customer requirements.

To ensure the highest standards of quality control, the company has implemented comprehensive testing processes at multiple stages of production. Through rigorous testing procedures, which include automated optical inspection (AOI) and X-ray inspection, the company guarantees the delivery of defect-free, high-performance SMD components. This commitment to quality has helped establish long-term partnerships with globally recognized brands, cementing the company's position as a trusted OEM supplier.

In addition to its manufacturing capabilities, this leading SMD mounting supplier places great emphasis on customer satisfaction. The company provides comprehensive technical support, personalized design consultations, and responsive customer service to assist clients at every stage of their product development journey. With a customer-centric approach, the company offers tailor-made solutions, ensuring the seamless integration of their SMD mounting technologies into diverse electronic applications.

As part of its commitment to sustainability and eco-friendly practices, the company has also implemented stringent measures to minimize its environmental impact. By adopting energy-efficient manufacturing processes and recycling programs, the company actively contributes to reducing carbon emissions and promoting sustainable production practices.

Looking ahead, this prominent SMD mounting supplier remains dedicated to continuous innovation and customer satisfaction. With its revamped operations, cutting-edge manufacturing techniques, and customer-centric approach, the company is poised to redefine industry standards and solidify its position as a leading provider of SMD mounting solutions.

About [Company Name]:

[Company Name] is a renowned global SMD mounting supplier, recognized for its unparalleled commitment to quality, innovation, and customer satisfaction. With a diverse portfolio of cutting-edge SMD components and advanced manufacturing capabilities, the company serves a wide range of industries, delivering customized solutions that consistently exceed customer expectations.

Company News & Blog

Pcb Printing Service Suppliers: Your Go-To Resource for Quality Board Printing

PCB Printing Service Suppliers Revolutionize Manufacturing ProcessIn today's ever-evolving world, industries are constantly seeking innovative solutions to improve efficiency and productivity. One sector that has seen a significant transformation in recent years is the electronics manufacturing industry. With the advent of PCB (Printed Circuit Board) printing services, manufacturers can now streamline their production process and bring products to market faster than ever before.PCB printing involves creating the base component of electronic devices by printing conductive pathways on an insulating substrate. This technology has revolutionized the manufacturing industry, as it eliminates the need for time-consuming and expensive manual soldering of components onto circuit boards. Instead, PCB printing allows for automated assembly, reducing manufacturing costs and increasing production speeds.One of the leading players in the PCB printing service industry is a well-established company that has been providing innovative solutions for electronic manufacturing for over a decade. With their cutting-edge technology and commitment to customer satisfaction, they have become a trusted partner for numerous companies worldwide.This PCB printing service supplier offers a wide range of solutions tailored to meet the diverse needs of their customers. Whether it is a small-scale prototype or large-scale production, they have the expertise and infrastructure to handle projects of any scale. With a team of highly skilled engineers and technicians, they ensure that every customer receives the highest quality printed circuit boards, meeting the strictest industry standards.To meet the growing demand for PCB printing services, this supplier has invested heavily in state-of-the-art manufacturing facilities. Equipped with the latest machinery and advanced technologies, their facilities boast a high level of automation, ensuring consistent quality and fast turnaround times. Additionally, they have implemented rigorous quality control measures at every stage of the production process to ensure that every PCB meets the highest standards of functionality and reliability.Beyond the technological advancements, this supplier places great emphasis on customer satisfaction. They understand that each customer has unique requirements and strive to provide customized solutions that meet their specific needs. Whether it is offering design support, optimizing production processes, or providing timely delivery, they go above and beyond to exceed customer expectations.This commitment to customer satisfaction has earned them an excellent reputation in the industry. Numerous companies across various sectors, including automotive, aerospace, consumer electronics, and medical devices, rely on their PCB printing services. The supplier's ability to meet the stringent demands of these industries is a testament to their professionalism and dedication to excellence.Furthermore, this PCB printing service supplier believes in sustainable manufacturing practices. They prioritize environmental conservation by implementing eco-friendly processes and adhering to regulatory guidelines. They constantly explore new technologies and materials that minimize waste and maximize energy efficiency. By partnering with this supplier, companies can ensure that their manufacturing processes align with their sustainability goals, contributing to a cleaner and greener future.In conclusion, PCB printing service suppliers have revolutionized the electronics manufacturing industry, allowing for faster and more efficient production processes. This particular supplier's commitment to innovation, quality, customer satisfaction, and sustainability has made them a leader in the field. As technology continues to advance, the future of PCB printing looks promising, with even greater improvements expected in the coming years.

High-Quality PCB PCBA Supplier: Ensuring Exceptional Standards in Electronic Manufacturing

High-Quality PCB PCBA Supplier Enhances Manufacturing SolutionsGlobal Circuits Ltd. has emerged as a leading provider of high-quality PCB (Printed Circuit Board) PCBA (Printed Circuit Board Assembly) solutions with its state-of-the-art manufacturing capabilities. With a commitment to delivering superior products and services, the company has become a trusted partner for businesses around the world.Global Circuits Ltd., a renowned PCB PCBA supplier, has carved a niche for itself by providing innovative and reliable solutions to meet the demanding requirements of the electronics industry. The company's extensive range of products and services caters to a diverse customer base, including manufacturers of consumer electronics, automotive systems, industrial equipment, and more.One of the key aspects of Global Circuits' success lies in its commitment to quality. The company ensures that all its products meet stringent quality standards, adhering to industry-specific certifications such as ISO 9001, ISO 13485, and ISO/TS 16949. With a dedicated quality control team and advanced testing equipment, Global Circuits Ltd. guarantees the reliability and performance of its PCBs and PCBA solutions.Global Circuits Ltd. offers a comprehensive range of PCBs, including single-sided, double-sided, and multi-layered boards. These PCBs are manufactured using high-quality materials and state-of-the-art manufacturing processes, ensuring excellent conductivity, durability, and performance. The company's expertise also extends to flexible PCBs, rigid-flex PCBs, and metal-core PCBs, providing customers with versatile solutions for their specific application needs.In addition to PCBs, Global Circuits Ltd.'s PCBA manufacturing capabilities have set it apart from its competitors. The company's advanced assembly lines, equipped with cutting-edge machinery and technology, enable the efficient production of complex circuit board assemblies. With a team of skilled technicians and engineers, Global Circuits Ltd. ensures accurate component placement, soldering, and testing, resulting in high-quality PCBA products.The company's flexible manufacturing processes allow for customized solutions, accommodating various design specifications and production quantities. Whether it is small-scale prototyping or large-scale production runs, Global Circuits Ltd. has the capacity and expertise to meet the unique requirements of each customer. With a focus on efficient production and prompt delivery, the company strives to provide a competitive advantage to its clients.Global Circuits Ltd. also values its commitment to sustainability and environmental responsibility. The company follows eco-friendly practices throughout its manufacturing processes, minimizing waste generation, and promoting efficient energy utilization. By adhering to strict environmental regulations and certifications, Global Circuits Ltd. ensures that its operations do not compromise the well-being of the planet.Furthermore, customer satisfaction forms the core of Global Circuits Ltd.'s business philosophy. The company's dedicated sales and customer support teams work closely with clients to understand their requirements and provide tailored solutions. From initial design consultation to post-production assistance, Global Circuits Ltd. maintains open lines of communication, ensuring a smooth and fulfilling customer experience.In a rapidly evolving industry, Global Circuits Ltd. remains at the forefront by investing in research and development. The company continuously explores emerging technologies and manufacturing techniques to enhance its products and services. By staying ahead of industry trends, Global Circuits Ltd. reaffirms its commitment to delivering innovative solutions that meet the evolving needs of its customers.As a high-quality PCB PCBA supplier, Global Circuits Ltd. has cemented its position as a reliable partner for businesses seeking superior electronic manufacturing solutions. With its commitment to quality, advanced manufacturing capabilities, and customer-centric approach, the company continues to drive innovation and excellence in the industry.###

Discover the Latest Insights on 6 Layer PCB Fabrication in China

Title: China Emerging as a Global Leader in 6-Layer PCB FabricationIntroduction (100 words):China, renowned for its manufacturing prowess, is making remarkable strides in the field of electronics manufacturing, specifically in the production of 6-layer PCBs (Printed Circuit Boards). PCBs have become vital components of numerous electronic devices, ranging from smartphones to automotive systems. China's continuous investments in research and development, coupled with its large-scale production capabilities, have positioned the country as a global leader in the PCB fabrication industry. This article will explore the growth of 6-layer PCB fabrication in China, shedding light on the country's advances and the potential impacts of these developments.Growth and Innovations in China's 6-Layer PCB Fabrication (300 words):China's electronics manufacturing industry has experienced significant growth over the past few decades, fostering an environment conducive to technological breakthroughs. With the increasing demand for thinner and more compact electronic devices, 6-layer PCBs have emerged as a preferred choice due to their enhanced functionality and larger integration capacity. China, recognizing this trend, has been at the forefront of developing innovative solutions for 6-layer PCB fabrication.The integration of advanced technologies, such as surface mount technology, has played a crucial role in enhancing China's manufacturing capabilities. This technology allows for the placement of electronic components directly on the PCB surface, effectively reducing the size and improving the overall efficiency of the electronic devices. China's extensive knowledge and experience in incorporating surface mount technology have given the country an edge in 6-layer PCB fabrication.Moreover, China's robust research and development ecosystem, supported by a multitude of universities and research institutions, has paved the way for numerous breakthroughs in PCB manufacturing technologies. These advancements have resulted in higher production yields, improved signal transmission, and reduced power consumption. China's focus on innovation and continuous improvement has strengthened the global competitiveness of its 6-layer PCBs.Industry Collaboration and Market Opportunities (200 words):China's 6-layer PCB fabrication industry has not only thrived on domestic demand but also gained significant traction in international markets. The country's cost-effective manufacturing capabilities, coupled with its commitment to quality, have attracted major global players to collaborate with Chinese PCB manufacturers. Collaborations provide these companies access to cutting-edge technologies while allowing Chinese manufacturers the opportunity to expand their market reach.Furthermore, the rapid growth of sectors such as telecommunications, automotive, healthcare, and consumer electronics across the world offers immense market opportunities for China's 6-layer PCB fabrication industry. As electronic devices become increasingly sophisticated, the demand for PCBs with higher layer counts will continue to rise. China's ability to meet this demand efficiently and at competitive prices positions it well to cater to global markets in the coming years.Conclusion (200 words):China's rapid emergence as a global leader in 6-layer PCB fabrication showcases the country's unwavering commitment to technological advancements and manufacturing excellence. Through investments in research and development, adoption of advanced manufacturing technologies, and collaborations with international partners, China has established itself as a major player in the PCB industry.As the demand for smaller, more powerful electronic devices grows, so too will the demand for 6-layer PCBs. With its expertise in surface mount technology, improved production yields, and cost-effective production capabilities, China is poised to serve as a key supplier for global industries in need of 6-layer PCB fabrication.Looking ahead, further advancements in materials, miniaturization techniques, and automation will continue to drive the growth of China's 6-layer PCB fabrication industry. As the country further solidifies its position as an electronics manufacturing hub, it will be interesting to see how China's PCB industry evolves in the face of technological advancements and changing market dynamics.

Top Copper PCB Manufacturers for OEMs

Title: Leading Copper PCB Manufacturer Unveils Innovative Solutions for Diverse IndustriesIntroduction:[OEM Copper PCB Manufacturers] has emerged as a global leader in the production of high-quality copper PCBs, catering to a wide range of industries. With its commitment to innovation, precision, and reliability, the company has built a solid reputation among its clientele. Through their cutting-edge technologies and dedication to customer satisfaction, [OEM Copper PCB Manufacturers] has continually elevated industry standards, making them the go-to choice for businesses worldwide.Innovative Manufacturing Techniques and Equipment:Recognizing the importance of advanced technology in the manufacturing process, [OEM Copper PCB Manufacturers] has heavily invested in state-of-the-art machinery and equipment. These advanced capabilities enable them to produce exceptional copper PCBs that meet the stringent demands of modern industries.The company's manufacturing process begins with meticulous research and development, with their team of experts constantly exploring new materials and techniques to enhance the performance of their PCBs. By collaborating with industry-leading experts, [OEM Copper PCB Manufacturers] stays at the forefront of technological advancements.Quality Management Systems:Quality control is of utmost importance to [OEM Copper PCB Manufacturers], and they have established stringent processes to ensure the reliability and performance of their products. They adhere to international standards such as ISO 9001 and ISO 14001. These certifications highlight the company's commitment to delivering top-notch PCBs with minimal environmental impact.Furthermore, [OEM Copper PCB Manufacturers] employs a comprehensive quality management system that includes rigorous testing at every stage of production. From raw material inspection to finished product testing, they leave no stone unturned in guaranteeing the highest levels of quality and performance.Catering to Diverse Industries:With their diverse clientele, [OEM Copper PCB Manufacturers] understands the unique requirements of various industries. They have successfully supplied copper PCBs to sectors such as telecommunications, automotive, aerospace, medical, consumer electronics, and more.Telecommunications: The demand for high-speed, reliable communication systems continues to grow. [OEM Copper PCB Manufacturers] has developed copper PCBs that minimize signal loss and offer superior transmission capabilities, meeting the industry's stringent standards for performance.Automotive: The automotive industry is increasingly reliant on advanced PCBs for vehicle systems and electronics. [OEM Copper PCB Manufacturers] provides durable and high-performance copper PCBs that can withstand the challenging automotive environments.Aerospace: The aerospace industry demands PCBs that can withstand extreme temperatures, vibrations, and other harsh conditions. [OEM Copper PCB Manufacturers] meets these requirements with their rugged and high-reliability copper PCBs, ensuring the safety and performance of critical aerospace applications.Medical: Precision and reliability are critical in the medical industry. [OEM Copper PCB Manufacturers] produces copper PCBs that meet the strict regulatory standards for medical devices, contributing to advancements in healthcare technology.Consumer Electronics: The ever-evolving consumer electronics sector requires PCBs that offer high-density interconnections and optimal performance. [OEM Copper PCB Manufacturers] manufactures copper PCBs that support miniaturization and enhanced functionality demanded by modern electronic devices.Environmental Commitment:In addition to producing high-quality products, [OEM Copper PCB Manufacturers] has also embraced sustainability practices. They prioritize responsible sourcing of materials and minimize the environmental impact of their manufacturing processes. By adhering to stringent waste management and recycling practices, [OEM Copper PCB Manufacturers] ensures that their operations align with global environmental regulations.Conclusion:As a leading supplier of copper PCBs, [OEM Copper PCB Manufacturers] continues to push the boundaries of innovation, reliability, and quality. With their state-of-the-art manufacturing processes, commitment to customer satisfaction, and contributions to various industries, the company has cemented its position as a reliable partner for businesses worldwide. As technologies evolve, [OEM Copper PCB Manufacturers] remains at the forefront, continually pushing the boundaries of what copper PCBs can achieve.

Enhance Efficiency and Quality with Professional PCB Assembly Services

[Headline]Expanding its Reach and Expertise: Leading Electronic Manufacturer Enhances OEM PCB Assembly Services[Subheading]{Company Name}, an industry-leading provider of cutting-edge electronic solutions, has announced an upgrade to its OEM PCB Assembly Services. With a commitment to technological advancement and customer satisfaction, the company aims to strengthen its position as a trusted partner in electronics manufacturing.[Date][City], [State], [Country] - {Company Name}, a renowned electronic manufacturer with a reputation for quality and excellence, is pleased to unveil the enhanced OEM PCB Assembly Services. This significant upgrade aligns with the company's dedication to innovation and customer-focused solutions.[Company Introduction]Established in [year], {Company Name} has been at the forefront of the electronics manufacturing industry, successfully delivering advanced electronic solutions to a global clientele. With state-of-the-art facilities and a highly skilled workforce, the company has built a solid reputation for excellence, precision, and reliability.[Preamble]Recognizing the evolving needs of the electronics market, {Company Name} has invested in enhancing its OEM PCB Assembly Services. By leveraging its technological expertise and rigorous quality standards, the company aims to provide even more comprehensive and efficient assembly solutions to its clients.[Expansion of Facilities]As part of this upgrade, {Company Name} has expanded its manufacturing facilities, ensuring a significant increase in production capacity. The enlarged facilities now allow for the simultaneous production of multiple complex circuit boards, enabling faster order fulfillment and reduced lead times.[Technological Advancements]The enhanced OEM PCB Assembly Services also benefit from a comprehensive range of technological advancements. {Company Name} has integrated cutting-edge technologies, such as automated surface mount technology (SMT) lines and precision robotic assembly, into its assembly processes. These advancements significantly streamline the manufacturing process, ensuring higher precision, improved quality control, and decreased production costs.[Quality Assurance]{Company Name}'s commitment to quality assurance remains paramount throughout its upgraded OEM PCB Assembly Services. The company adheres to stringent quality control measures at every stage of production, employing advanced inspection techniques and industry-standard testing protocols to guarantee the durability, functionality, and reliability of the assembled PCBs.[Customization and Flexibility]Understanding the diverse requirements of its clients, {Company Name} offers flexible and customizable assembly solutions to accommodate a wide variety of PCB designs. From single and double-sided boards to multi-layered PCBs, the company can handle a diverse range of projects with varying complexities. Furthermore, {Company Name} provides comprehensive design review and optimization services, working closely with its clients to ensure the successful realization of their electronic concepts.[Environmental Responsibility]In line with its commitment to environmental stewardship, {Company Name} has implemented environmentally friendly practices across its manufacturing processes. The company adheres to industry regulations, ensuring minimal waste generation and responsible disposal of potentially harmful electronic waste. By doing so, {Company Name} demonstrates its dedication to sustainability while providing exceptional electronic solutions.[Conclusion]With the upgraded OEM PCB Assembly Services, {Company Name} further solidifies its position as a leading electronic manufacturer. The expanded facilities, integration of cutting-edge technologies, and unwavering commitment to quality assurance enable the company to deliver comprehensive and cutting-edge assembly solutions to its clients. Through its exceptional service, {Company Name} continues to drive innovation and exceed customer expectations in the ever-evolving electronics industry.

China's Leading Suppliers of Chip LED SMD Products Discovered in Recent News

Title: Expansion of China's Chip LED SMD Suppliers Sparks Market GrowthIntroduction:China's chip LED SMD market is witnessing substantial growth as suppliers expand production capabilities to meet the increasing global demand. With a strategic combination of advanced technology, well-established infrastructure, and competitive pricing, Chinese manufacturers are positioning themselves as key players in the global LED industry. This article explores the recent developments in China's chip LED SMD market and how suppliers are driving the growth of this sector.Embracing Advanced Technology:China's chip LED SMD suppliers, including [Supplier A] and [Supplier B], have been at the forefront of adopting cutting-edge technologies to enhance the production of their LED products. By investing in research and development, these suppliers have successfully improved the quality and efficiency of their chip LED SMDs, making them highly sought after in both domestic and international markets.[SUPPLIER A] has introduced innovative manufacturing processes that ensure the consistent performance and durability of their chip LED SMDs. By utilizing advanced automation and quality control systems, they have optimized production yields and minimized defects, resulting in a higher overall product quality.Similarly, [SUPPLIER B] has focused on developing environmentally friendly and energy-efficient chip LED SMDs. Their commitment to sustainable manufacturing practices has enabled them to gain a competitive edge, particularly in regions where environmental regulations are stringent, such as Europe and North America.Expanding Production Capacity:Recognizing the growing demand for chip LED SMDs, Chinese suppliers have significantly expanded their production capacity to meet domestic and international requirements. With the support of the government's favorable policies and investments in infrastructure, these companies have built advanced manufacturing facilities that can cater to diverse market segments.[SUPPLIER A] has recently inaugurated a state-of-the-art production plant, equipped with the latest machinery and production lines. This expansion has quadrupled their chip LED SMD production capacity, allowing them to fulfill large-scale orders with shorter lead times. Moreover, they have strategically located their manufacturing facilities to ensure easy access to raw materials and transportation networks, enabling efficient supply chain management.[SUPPLIER B] has also taken steps to boost their chip LED SMD production capacity. By implementing lean manufacturing principles and utilizing intelligent production systems, they have achieved higher production efficiency and reduced production costs. This expansion has positively impacted their competitiveness in the global market, driving their export volumes to record highs.Competitive Pricing and Market Penetration:Chinese chip LED SMD suppliers have gained a significant advantage over their international competitors by offering cost-effective solutions without compromising quality. The competitive pricing, coupled with improved performance, has positioned them as preferred suppliers for both small-scale and large-scale projects.Due to economies of scale and lower manufacturing costs, Chinese suppliers have the ability to offer chip LED SMDs at highly competitive prices. This advantage has allowed them to penetrate various industries, including automotive, consumer electronics, and lighting, further expanding their market share globally.Moreover, the extensive distribution networks established by Chinese suppliers have facilitated their market penetration efforts. Collaborations with local distributors and partnerships with international manufacturers have ensured a wide reach for their chip LED SMD products, enabling them to serve customers in all corners of the globe.Conclusion:China's chip LED SMD suppliers have emerged as leaders in the global LED industry by embracing advanced technologies, expanding production capacities, and offering competitive pricing. With continuous investments in research and development, these suppliers are driving the growth of the chip LED SMD market and meeting the evolving demands of customers worldwide. As they continue to innovate and enhance production capabilities, their presence in the industry is set to shape the future of chip LED SMDs.

Top Component Manufacturers: Boosting Performance and Efficiency for OEMs

Title: Leading OEM Component Manufacturers Revolutionize the Industry with Innovative OfferingsIntroduction:In today's ever-evolving technological landscape, Original Equipment Manufacturers (OEMs) continue to play a vital role in the development and production of cutting-edge products across various industries. Among these OEM manufacturers, a few prominent companies have established themselves as pioneers in the market, revolutionizing the industry with their innovative offerings. This article will focus on two leading OEM component manufacturers, known for their commitment to quality, reliability, and continuous innovation.Company A: Transforming OEM Components for ExcellenceWith a proven track record spanning several decades, Company A stands tall as one of the most trusted names in the OEM component manufacturing industry. Specializing in the production of electronic components, this company has been instrumental in supplying high-quality parts to renowned OEMs worldwide.Company A's commitment to excellence is showcased in its state-of-the-art manufacturing facilities, equipped with cutting-edge technology and staffed by a team of highly skilled professionals. Rigorous quality control measures are implemented at every stage of the manufacturing process, ensuring that customers receive components of the highest standards. This unwavering dedication to quality has earned Company A an enviable reputation among OEMs and end-users.In addition to its exceptional manufacturing capabilities, Company A places great emphasis on research and development. By investing in continuous innovation, they stay at the forefront of technological advancements, enabling them to meet the ever-growing demands of OEMs. Their extensive product portfolio includes a wide range of components, such as integrated circuits, connectors, resistors, capacitors, and much more.Recognizing the importance of sustainability, Company A has also taken significant steps to reduce its environmental impact. By implementing eco-friendly practices throughout their operations, they remain committed to minimizing waste generation and optimizing energy consumption.Company B: Pioneering Solutions for OEMsCompany B's commitment to delivering reliable and innovative solutions has positioned it as a leading OEM component manufacturer in the industry. With expertise in mechanical and electromechanical components, this company has earned the trust of OEMs across multiple sectors.Equipped with advanced design and engineering capabilities, Company B excels in translating conceptual ideas into practical and functional products. Their team of experienced engineers works closely with OEMs to understand their specific requirements and develop tailor-made solutions that meet and exceed expectations.Company B takes pride in its comprehensive manufacturing facilities, which feature cutting-edge machinery and emphasize precision manufacturing techniques. Adhering to strict quality standards ensures that their components exhibit exceptional reliability and longevity, allowing OEMs to integrate them seamlessly into their applications.Driven by a culture of innovation, Company B invests heavily in research and development. By collaborating with OEMs, they identify industry challenges and strive to address them with groundbreaking solutions. Their extensive product range includes gears, springs, assemblies, and a myriad of other precision components that cater to a diverse range of industries.Additionally, Company B places great importance on sustainability by focusing on eco-friendly manufacturing practices and minimizing waste generation. Their commitment to corporate social responsibility is reflected in their responsibly sourced materials and dedication to reducing their environmental footprint.Conclusion:As OEM component manufacturers, both Company A and Company B have demonstrated their commitment to excellence accompanied by continuous innovation and sustainable practices. Through their cutting-edge solutions and unparalleled quality, these companies have solidified their position as industry leaders, setting new benchmarks for OEM manufacturing. With a customer-centric approach and an unrelenting pursuit of technological advancement, these OEM component manufacturers are poised to shape the future of the industry.

Top Through Hole PCB Suppliers: Key Insights from Industry Experts

Title: Leading Through-Hole PCB Suppliers Take Their Business to New HeightsIntroduction:Through-hole PCBs (Printed Circuit Boards) are fundamental components used in a wide range of electronic devices, from household appliances to complex industrial machinery. As the demand for quality and reliable PCB solutions continues to rise, OEM Through-Hole PCB Suppliers, renowned for their exceptional track record and dedication to customer satisfaction, are stepping up their game to meet the evolving industry requirements.Company Background:(Company Name) is a leading player in the OEM Through-Hole PCB supply chain, trusted by numerous industries for their cutting-edge manufacturing capabilities and ability to deliver high-quality circuit boards. With years of experience and expertise, (Company Name) has established itself as an industry pioneer, continually pushing the boundaries of innovation and providing tailor-made, cost-effective solutions to their clients.Expanding Production Capacity:In response to the surging demand for Through-Hole PCBs, (Company Name) recently announced a significant expansion of its production capacity. The company plans to invest heavily in state-of-the-art equipment, advanced technologies, and skilled professionals to ensure faster turnaround times, increased production volumes, and enhanced quality control measures.By upgrading their manufacturing facilities, (Company Name) aims to meet the diverse needs of its ever-growing customer base, which includes key players in the automotive, aerospace, telecommunications, and consumer electronics sectors. With this strategic expansion, the company aspires to stay ahead of the competition and solidify its position as a premier Through-Hole PCB supplier.Adopting Cutting-Edge Technologies:Recognizing the importance of innovation in the PCB industry, (Company Name) has also prioritized the adoption of cutting-edge technologies. The company has collaborated with renowned research institutions and industry experts to explore emerging trends and improve its product offerings continually. By staying at the forefront of technological advancements, (Company Name) aims to take advantage of the latest developments, such as smaller PCB footprints, increased density, and improved speeds.Furthermore, (Company Name) has wholeheartedly embraced automation in its manufacturing processes. Automation not only ensures precision and accuracy but also helps eliminate human error, reducing production time and improving overall efficiency. With such advancements, (Company Name) can cater to the evolving demands of its clients, who now require PCBs that can handle complex designs and high-speed data transfers.Commitment to Quality:One of the key factors that have contributed to the success of (Company Name) is its unwavering commitment to quality. The company recognizes the critical role that PCBs play in the overall performance of electronic devices, and thus, places paramount importance on stringent quality control measures.(Company Name) adheres to strict industry standards in every aspect of its operations, ensuring that all PCBs meet or exceed customer expectations. By conducting rigorous testing at various stages of the manufacturing process, (Company Name) guarantees the reliability, durability, and functionality of its products. This steadfast dedication to quality has earned the company an impeccable reputation in the industry and the trust of clients worldwide.Future Prospects and Sustainability:As the demand for Through-Hole PCBs continues to rise, (Company Name) is actively exploring sustainable manufacturing practices. By employing environmentally friendly materials and adopting energy-efficient processes, the company endeavors to minimize its carbon footprint and contribute to a greener environment.Furthermore, (Company Name) is focused on strengthening its partnerships with clients, nurturing long-term relationships, and understanding their unique requirements. By offering customized solutions, comprehensive technical support, and excellent customer service, the company aims to foster customer loyalty and sustain its position as a preferred Through-Hole PCB supplier.In conclusion, (Company Name) is at the forefront of the Through-Hole PCB industry, continuously striving for excellence in quality, innovation, and customer satisfaction. With their expansion plans, cutting-edge technologies, and commitment to sustainable practices, (Company Name) is well-positioned to address the demands of an ever-evolving industry.

Optimizing PCB Assembly: A Flexible Solution for Electronics Manufacturing

[Company Name] Establishes State-of-the-Art Flexible PCB Assembly Factory to Meet Growing Demand[City, Date] - [Company Name], a global leader in electronic manufacturing services, announced the establishment of a cutting-edge flexible PCB assembly factory to cater to the increasing demand for flexible printed circuit board (PCB) technology in various industries.With the rise of miniaturized and portable electronic devices, such as smartphones, wearables, and IoT devices, flexible PCBs have become a critical component in ensuring optimal performance and functionality. These flexible boards allow for intricate designs, impact resistance, and space efficiency, making them ideal for products that require bending or folding.The new flexible PCB assembly factory, located in [City], is equipped with state-of-the-art machinery and technology, ensuring the highest standards of quality, efficiency, and flexibility. This facility combines automation with skilled human expertise for the seamless production of flexible PCBs, from design and development to full-scale manufacturing."Our investment in this new factory highlights our commitment to serving our customers' evolving needs in the ever-changing electronics industry," said [Company Name]'s CEO. "We are excited to offer an end-to-end solution for flexible PCB assembly, allowing our clients to capitalize on the growing demand for innovative electronic devices."The factory's advanced machinery includes cutting-edge automated assembly lines, precision component placement systems, and high-speed solder paste printers. These technological advancements enhance productivity while maintaining stringent quality control measures throughout the production process. Additionally, the factory is equipped with advanced testing and inspection tools to ensure the reliability and durability of each flexible PCB that leaves the facility.To support the factory's operations, [Company Name] has assembled a team of highly skilled engineers, technicians, and production experts. These professionals possess extensive experience in flexible PCB assembly and are adept at customizing solutions to meet clients' specific requirements.The flexible PCB assembly factory primarily serves industries such as telecommunications, consumer electronics, automotive, aerospace, and healthcare. These sectors demand reliable and robust flexible PCB solutions to address the evolving trends and demands of their respective markets.In alignment with its commitment to sustainability, [Company Name] has implemented eco-friendly manufacturing practices in the new assembly factory. These practices include the use of lead-free soldering materials, energy-efficient machinery, and waste reduction measures, ensuring the manufacturing process is eco-conscious.The establishment of this state-of-the-art factory not only bolsters [Company Name]'s position as a leader in the electronics manufacturing industry but also strengthens its ability to provide comprehensive end-to-end solutions for its global clientele. With this new facility, [Company Name] is poised to meet the growing demand for flexible PCB assembly and cater to the unique requirements of various industries.About [Company Name]:[Company Name] is a globally recognized leader in electronic manufacturing services, providing end-to-end solutions for a wide range of industries. The company specializes in PCB assembly, electronic design, prototyping, and full-scale manufacturing. With a commitment to innovation, quality, and customer satisfaction, [Company Name] strives to meet and exceed the ever-evolving demands of the electronics industry.For more information about [Company Name] and its flexible PCB assembly services, please visit [Company Website].###Note: The brand name has been removed from the provided text. Replace [Company Name] with the appropriate brand name when incorporating the content into an actual news article.

Top-Notch PCBA Service for High-Quality Results - A Must-Read News Content

[Company Name] Leads the Way in Providing High-Quality PCBA Services[date][City, State] - [Company Name], a leading provider of electronic manufacturing services, is revolutionizing the industry with its high-quality Printed Circuit Board Assembly (PCBA) services. With its state-of-the-art facilities and highly skilled team of experts, [Company Name] is meeting the growing demand for advanced PCBAs in various sectors, including consumer electronics, automotive, aerospace, and telecommunications.For over [number of years] years, [Company Name] has been at the forefront of delivering cutting-edge PCBA solutions to clients globally. By constantly investing in research and development, the company has built a strong reputation for its innovative techniques, meticulous attention to detail, and commitment to delivering high-quality products.One of the key factors that sets [Company Name] apart is its advanced manufacturing facilities. Equipped with the latest technologies and automated machinery, the company ensures precision and efficiency throughout the PCBA production process. This enables [Company Name] to meet strict quality control standards and deliver consistently excellent results.Furthermore, [Company Name] boasts a team of highly skilled engineers and technicians who are experts in PCB design, assembly, and testing. These professionals undergo regular training to keep up with the rapidly evolving industry trends and technological advancements. With a deep understanding of the unique requirements and challenges faced by each client, [Company Name] ensures personalized and tailored PCBA solutions.[Company Name] serves a diverse range of industries, including consumer electronics, where the demand for smaller, faster, and more reliable PCBAs is on the rise. The company leverages its expertise to manufacture cutting-edge PCBAs for smartphones, tablets, wearables, and other electronic devices. By utilizing advanced materials and production techniques, [Company Name] meets the ever-increasing consumer expectations for sleek design and flawless performance.In the automotive sector, where safety and reliability are paramount, [Company Name] excels in delivering PCBAs for advanced driver-assistance systems (ADAS), infotainment systems, and electronic control units (ECUs). By incorporating stringent quality control measures and adhering to industry regulations, [Company Name] ensures the highest level of performance and durability for its automotive PCBAs.The aerospace industry also relies heavily on robust and faultless PCBAs for communication systems, navigation equipment, and avionics. Here, [Company Name] plays a crucial role by delivering PCBA services that meet the rigorous standards imposed by aerospace regulatory bodies. By combining its expertise with strict adherence to quality control standards, [Company Name] provides reliable and resilient PCBAs that withstand extreme conditions and operate flawlessly in aerospace applications.Moreover, [Company Name] caters to the telecommunications industry, which depends heavily on high-speed data transmission and advanced network infrastructure. By leveraging its expertise in PCB design and assembly, [Company Name] offers innovative PCBA solutions that support the development of faster and more efficient communication systems. From routers and switches to telecommunications equipment, [Company Name] is a trusted partner in delivering reliable and high-performing PCBAs.As the demand for high-quality PCBAs continues to rise, [Company Name] remains committed to staying at the forefront of the industry. The company invests in continuous improvement initiatives, research and development, and the adoption of new technologies. By doing so, [Company Name] ensures that its clients receive the most advanced and reliable PCBAs to fuel their success in today's rapidly evolving landscape.About [Company Name]:[Company Name] is a [location]-based electronic manufacturing services provider, specializing in high-quality PCBA solutions. With state-of-the-art facilities and a team of skilled professionals, the company is dedicated to meeting and exceeding client expectations. [Company Name] serves clients across various industries, including consumer electronics, automotive, aerospace, and telecommunications.For media inquiries, please contact:[Company Name][Contact Person's Name][Title][Email][Phone number]###Note: Please insert the brand name and other missing details in the sections indicated by {}.