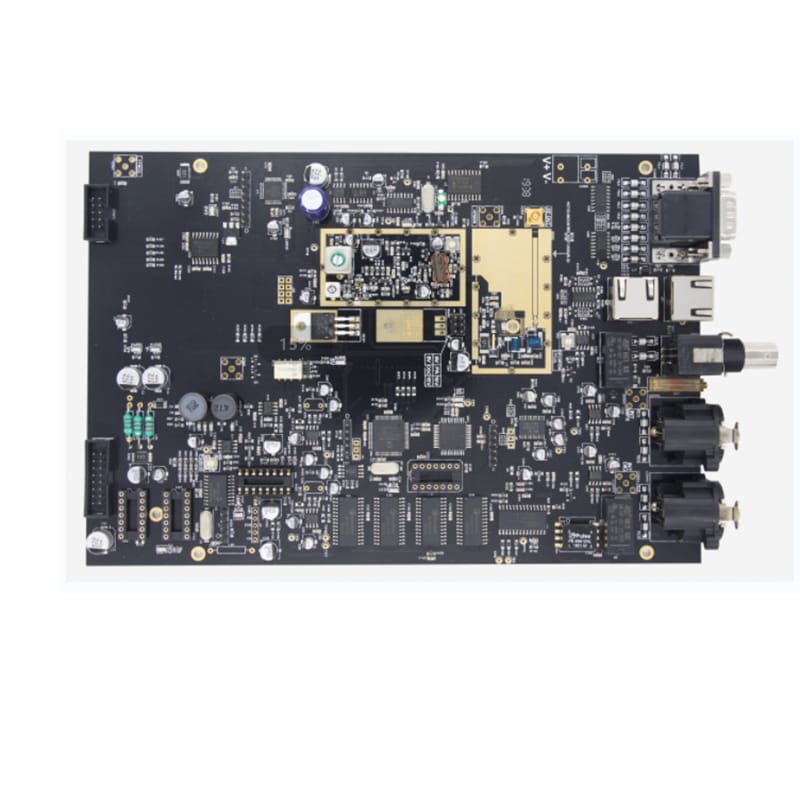

Top-Quality Fabrication Services for High-Quality Boards

By:Admin

With the growing demand for advanced technology in various industries, the need for high-quality board fabrication has never been more essential. Companies across the world are looking for reliable partners to provide them with cutting-edge fabrication solutions that can meet their specific requirements. One company that has been leading the way in this field is {}.

{} is a renowned name in the world of high-quality board fabrication. The company has built a reputation for delivering precision and innovation in every product they offer. Their state-of-the-art facilities and commitment to excellence have made them a trusted partner for businesses looking for top-notch fabrication services.

At {}'s core is a dedication to producing highly reliable and advanced circuit boards that meet the highest industry standards. The company leverages the latest technology and employs a team of skilled engineers and technicians to ensure that each product is of the highest quality. With a focus on continuous improvement and innovation, {} has remained at the forefront of the industry, consistently exceeding customer expectations with their exceptional solutions.

One of the key factors that set {} apart from its competitors is its commitment to providing custom fabrication solutions. The company works closely with its clients to understand their unique needs and preferences, and then develops tailored solutions that perfectly align with their requirements. This personalized approach has enabled {} to build long-lasting partnerships with a diverse range of clients, from small businesses to multinational corporations.

{}'s broad range of capabilities includes single-sided, double-sided, and multi-layered board fabrication, as well as flexible and rigid-flex boards. The company also offers a variety of finishes and materials to ensure that they can cater to a wide spectrum of industry needs. Whether it's for aerospace, automotive, medical, or telecommunications applications, {} has the expertise and resources to deliver high-quality boards that meet the most stringent quality and performance standards.

Another factor that sets {} apart is its unwavering commitment to quality and reliability. The company's rigorous quality control processes ensure that every product that leaves their facilities is of the highest standard. With comprehensive testing and inspection procedures in place, {} guarantees that their customers receive boards that are free from defects and built to last.

In addition to their commitment to quality, {} also places a strong emphasis on sustainability and environmental responsibility. The company actively seeks out eco-friendly materials and manufacturing processes to minimize their impact on the environment. By integrating sustainable practices into their operations, {} is not only fulfilling their corporate social responsibilities but also providing their customers with environmentally conscious solutions.

As technology continues to advance at a rapid pace, the demand for high-quality board fabrication will only continue to grow. With a track record of excellence and a commitment to innovation, {} is well-positioned to meet the needs of the evolving industry. Their dedication to precision, customization, quality, and sustainability makes them a top choice for businesses looking for reliable fabrication partners.

In conclusion, {}'s focus on high-quality board fabrication combined with their dedication to precision and innovation has established them as a leader in the industry. The company's commitment to delivering custom solutions, strict quality control processes, and sustainable practices sets them apart from their competitors. As businesses continue to seek out advanced technology solutions, {} remains the go-to partner for high-quality board fabrication.

Company News & Blog

Top Supplier of PCB Assembly Components: Unveiling the Leading Provider in the Electronic Manufacturing Domain

[NEWS]Leader in PCB Assembly, Main Supplier, Continues to Excel in Electronics Manufacturing Industry[City Name], [State Name] - [Date] Main Supplier, a leading provider of high-quality PCB assembly services, continues to be at the forefront of the electronics manufacturing industry. With their top-of-the-line facilities, cutting-edge technology, and dedication to customer satisfaction, Main Supplier has established itself as a reliable partner for businesses across various sectors.Established in [Year], Main Supplier has been catering to the diverse needs of its clients by offering comprehensive turnkey solutions for all their PCB assembly requirements. Their state-of-the-art facilities, equipped with advanced machinery and capable of handling high-volume productions, ensure fast turnaround times without compromising on quality.One of the key drivers behind Main Supplier’s success has been its unwavering commitment to utilizing the latest technology in their assembly processes. The company constantly evolves its techniques and invests in upgrading its machinery, enabling them to stay ahead of the ever-changing industry demands. This dedication to innovation has placed Main Supplier in a position of strength in the market, allowing them to consistently deliver products of unmatched precision and reliability.In addition to keeping up with technological advancements, Main Supplier prioritizes quality control at every stage of the assembly process. With a strong focus on product reliability, the company strictly adheres to international standards and employs rigorous quality assurance procedures. By using only premium materials and components from trusted suppliers, Main Supplier ensures that their assembled PCBs meet and exceed the highest industry standards.Beyond their exceptional manufacturing capabilities, Main Supplier places significant emphasis on the customer experience. The company recognizes that every client has unique needs and strives to provide tailored solutions to match those requirements. By fostering strong relationships with their clients, Main Supplier understands the importance of open communication, timely delivery, and a cooperative approach to ensure customer satisfaction.Moreover, Main Supplier prides itself on its skilled workforce, comprising highly trained technicians and engineers with extensive experience in the field. This team of experts is well-equipped to handle complex projects and troubleshoot any potential issues that may arise during the assembly process. With their vast knowledge and attention to detail, Main Supplier guarantees unrivaled precision and quality in each product they deliver.Main Supplier’s dedication to excellence has garnered them numerous accolades and recognition in the industry. Their commitment to environmental sustainability and responsible manufacturing practices has earned them the trust and loyalty of clients globally. From automotive and aerospace to medical and consumer electronics, Main Supplier continues to be the preferred choice for PCB assembly requirements across diverse industries.Looking towards the future, Main Supplier remains committed to pushing boundaries and pioneering new advancements in PCB assembly. By investing in research and development, the company aims to stay ahead of emerging trends and provide innovative solutions to their clientele. Additionally, Main Supplier recognizes the importance of fostering sustainable practices and intends to continue minimizing their environmental impact through the use of eco-friendly materials and energy-efficient manufacturing processes.For more information about Main Supplier and their PCB assembly services, please visit their website [website URL]. ###[About Main Supplier]Main Supplier, headquartered in [City Name], [State Name], is a leading provider of high-quality PCB assembly services. With cutting-edge technology, state-of-the-art facilities, and a commitment to excellence, Main Supplier continues to exceed customer expectations in the electronics manufacturing industry. Their wide range of services and dedication to customer satisfaction make them a trusted partner for businesses across various sectors. To learn more about Main Supplier, please visit [website URL].

Custom PCBA Manufacturing Services: Get a Quote from a Leading Manufacturer

OEM PCBA Quote Manufacturer, a leader in the electronics manufacturing industry, is proud to announce their latest offerings for companies in need of high-quality printed circuit board assembly (PCBA) services. With a proven track record of excellence and a dedication to customer satisfaction, OEM PCBA Quote Manufacturer is the top choice for businesses looking to outsource their electronics manufacturing needs.Founded in [year], OEM PCBA Quote Manufacturer has quickly risen to prominence within the electronics manufacturing industry. Specializing in PCB assembly, the company has built a reputation for delivering top-of-the-line products and services to a wide range of clients. With a commitment to innovation and technology, OEM PCBA Quote Manufacturer continues to push the boundaries of what is possible in electronics manufacturing.As an OEM PCBA manufacturer, the company provides a full range of services to meet the diverse needs of their clients. This includes PCB fabrication, component sourcing, PCB assembly, and testing. By offering a comprehensive suite of services, OEM PCBA Quote Manufacturer is able to streamline the manufacturing process, reduce costs, and deliver products of the highest quality.One of the key advantages of working with OEM PCBA Quote Manufacturer is their ability to provide customized solutions for their clients. The company understands that every project is unique, and they take the time to fully comprehend the specific requirements of each client. With a team of experienced engineers and technicians, OEM PCBA Quote Manufacturer is able to provide tailored solutions that meet the exact specifications of their clients.In addition to their commitment to quality and customization, OEM PCBA Quote Manufacturer also places a strong emphasis on efficiency and cost-effectiveness. By leveraging their extensive network of suppliers and utilizing the latest manufacturing technologies, the company is able to reduce lead times and minimize production costs. This ultimately allows them to provide competitive pricing without compromising on the quality of their products.To further solidify their position as a leader in the industry, OEM PCBA Quote Manufacturer is constantly investing in research and development to stay ahead of the curve. By staying at the forefront of technological advancements and industry trends, the company is able to offer cutting-edge solutions that give their clients a competitive edge in the market.As a testament to their commitment to excellence, OEM PCBA Quote Manufacturer has received numerous accolades and certifications for their manufacturing processes and quality management systems. This includes ISO [number] certification, which demonstrates their adherence to international standards for quality and consistency.With their latest offerings, OEM PCBA Quote Manufacturer is poised to continue their legacy of delivering exceptional products and services to their clients. Whether it is a small-scale prototype or a large-scale production run, the company has the expertise and capabilities to handle projects of any size and complexity.In conclusion, OEM PCBA Quote Manufacturer is the go-to choice for companies in need of high-quality printed circuit board assembly services. With a proven track record of excellence, a dedication to customer satisfaction, and a commitment to innovation, the company is well-equipped to meet the diverse needs of their clients. As they continue to expand and innovate, OEM PCBA Quote Manufacturer is well-positioned to remain a leader in the electronics manufacturing industry for years to come.

Advanced Flex PCB Capabilities: What You Need to Know

Flex PCB Capabilities Growing in Response to Increased Demand for Flexible ElectronicsWith the rising demand for flexible electronic devices in various industries, the need for advanced flex PCB capabilities has become increasingly important. Flex PCB, or flexible printed circuit boards, are essential components in the production of flexible electronics such as wearable devices, smart gadgets, and automotive applications. This growing demand has led to the development of innovative flex PCB technologies, with companies like {} at the forefront of this industry.{} is a leading provider of advanced flex PCB solutions, offering a wide range of capabilities to meet the evolving needs of the electronics market. The company specializes in the design and production of flexible printed circuit boards, utilizing cutting-edge materials and state-of-the-art manufacturing processes to deliver high-quality and reliable products. With a focus on innovation and customer satisfaction, {} has established itself as a trusted partner for companies seeking flexible PCB solutions.One of the key capabilities offered by {} is the ability to produce complex flex PCB designs that require a high degree of flexibility and durability. Through the use of advanced materials such as polyimide and flexible coverlay, {} is able to create intricate PCB layouts that can withstand bending and flexing without compromising performance or reliability. This capability is particularly important in applications such as wearable devices and automotive sensors, where flexibility and durability are essential.In addition to complex designs, {} also offers a wide range of manufacturing options for flex PCBs, including single-sided, double-sided, and multi-layer flex circuits. This flexibility in manufacturing allows the company to meet the diverse requirements of its customers, whether they need a simple flex PCB for a consumer electronics product or a complex multi-layer flex circuit for a medical device. {}'s manufacturing capabilities are backed by stringent quality control processes, ensuring that each flex PCB meets the highest standards of performance and reliability.Another important aspect of {}'s flex PCB capabilities is its ability to offer quick turnaround times and prototyping services. As the demand for flexible electronics continues to grow, the need for fast and efficient PCB prototyping has become increasingly important. {}'s rapid prototyping capabilities allow its customers to quickly test and iterate on their designs, speeding up the product development cycle and bringing innovative products to market faster.Furthermore, {} is committed to continuous research and development in the field of flex PCB technologies. The company invests in state-of-the-art equipment and employs a team of skilled engineers and technicians who are dedicated to pushing the boundaries of flex PCB capabilities. By staying at the forefront of technological advancements, {} is able to anticipate and respond to the evolving needs of the electronics industry, offering its customers the latest advancements in flex PCB technologies.As a leading provider of flex PCB solutions, {} has established itself as a trusted partner for companies across various industries, including consumer electronics, healthcare, automotive, and aerospace. The company's commitment to quality, innovation, and customer satisfaction has earned it a strong reputation in the electronics market, making it the go-to choice for companies seeking reliable and high-performance flex PCB solutions.In conclusion, the growing demand for flexible electronics has spurred the development of advanced flex PCB capabilities, with companies like {} leading the way in this industry. By offering complex designs, flexible manufacturing options, rapid prototyping, and a commitment to research and development, {} is well-positioned to meet the evolving needs of the electronics market and continue to drive innovation in flex PCB technologies.

Top Through Hole PCB Suppliers: Key Insights from Industry Experts

Title: Leading Through-Hole PCB Suppliers Take Their Business to New HeightsIntroduction:Through-hole PCBs (Printed Circuit Boards) are fundamental components used in a wide range of electronic devices, from household appliances to complex industrial machinery. As the demand for quality and reliable PCB solutions continues to rise, OEM Through-Hole PCB Suppliers, renowned for their exceptional track record and dedication to customer satisfaction, are stepping up their game to meet the evolving industry requirements.Company Background:(Company Name) is a leading player in the OEM Through-Hole PCB supply chain, trusted by numerous industries for their cutting-edge manufacturing capabilities and ability to deliver high-quality circuit boards. With years of experience and expertise, (Company Name) has established itself as an industry pioneer, continually pushing the boundaries of innovation and providing tailor-made, cost-effective solutions to their clients.Expanding Production Capacity:In response to the surging demand for Through-Hole PCBs, (Company Name) recently announced a significant expansion of its production capacity. The company plans to invest heavily in state-of-the-art equipment, advanced technologies, and skilled professionals to ensure faster turnaround times, increased production volumes, and enhanced quality control measures.By upgrading their manufacturing facilities, (Company Name) aims to meet the diverse needs of its ever-growing customer base, which includes key players in the automotive, aerospace, telecommunications, and consumer electronics sectors. With this strategic expansion, the company aspires to stay ahead of the competition and solidify its position as a premier Through-Hole PCB supplier.Adopting Cutting-Edge Technologies:Recognizing the importance of innovation in the PCB industry, (Company Name) has also prioritized the adoption of cutting-edge technologies. The company has collaborated with renowned research institutions and industry experts to explore emerging trends and improve its product offerings continually. By staying at the forefront of technological advancements, (Company Name) aims to take advantage of the latest developments, such as smaller PCB footprints, increased density, and improved speeds.Furthermore, (Company Name) has wholeheartedly embraced automation in its manufacturing processes. Automation not only ensures precision and accuracy but also helps eliminate human error, reducing production time and improving overall efficiency. With such advancements, (Company Name) can cater to the evolving demands of its clients, who now require PCBs that can handle complex designs and high-speed data transfers.Commitment to Quality:One of the key factors that have contributed to the success of (Company Name) is its unwavering commitment to quality. The company recognizes the critical role that PCBs play in the overall performance of electronic devices, and thus, places paramount importance on stringent quality control measures.(Company Name) adheres to strict industry standards in every aspect of its operations, ensuring that all PCBs meet or exceed customer expectations. By conducting rigorous testing at various stages of the manufacturing process, (Company Name) guarantees the reliability, durability, and functionality of its products. This steadfast dedication to quality has earned the company an impeccable reputation in the industry and the trust of clients worldwide.Future Prospects and Sustainability:As the demand for Through-Hole PCBs continues to rise, (Company Name) is actively exploring sustainable manufacturing practices. By employing environmentally friendly materials and adopting energy-efficient processes, the company endeavors to minimize its carbon footprint and contribute to a greener environment.Furthermore, (Company Name) is focused on strengthening its partnerships with clients, nurturing long-term relationships, and understanding their unique requirements. By offering customized solutions, comprehensive technical support, and excellent customer service, the company aims to foster customer loyalty and sustain its position as a preferred Through-Hole PCB supplier.In conclusion, (Company Name) is at the forefront of the Through-Hole PCB industry, continuously striving for excellence in quality, innovation, and customer satisfaction. With their expansion plans, cutting-edge technologies, and commitment to sustainable practices, (Company Name) is well-positioned to address the demands of an ever-evolving industry.

China PCB Sheet Manufacturers: A Comprehensive Guide

Title: PCB Sheet Manufacturers in China: Meeting Global Demands with High-Quality SolutionsIntroduction:In today's interconnected world, Printed Circuit Boards (PCBs) play a vital role in nearly every electronic device we use. China has emerged as a global leader in PCB manufacturing, meeting the increasing demands of diverse industries. Among the prominent manufacturers in China, one company has been consistently offering high-quality PCB sheets to cater to the evolving needs of the global market. This article explores the company's impressive capabilities, unwavering commitment to quality, and how it contributes to China's reputation as a reliable leader in PCB manufacturing.Company Background and Vision:Established in {year}, {Company Name} has quickly become a trusted name in the field of PCB manufacturing in China. Its state-of-the-art facilities and cutting-edge technology enable the company to produce a wide range of PCB sheets with impeccable precision and quality. With a firm commitment to customer satisfaction, the company focuses on delivering innovative solutions while maintaining competitive prices. Its vision is to become a preferred partner for global businesses seeking high-quality PCB sheets.Advanced Manufacturing Facilities:{Company Name} boasts a modern manufacturing facility, equipped with the latest machinery and tools necessary for efficient production. The company's advanced capabilities include automated production lines, precision etching machines, and technologically advanced testing equipment. These facilities ensure the manufacturing process is streamlined and guarantees the highest quality of PCB sheets.Product Range and Customized Solutions:Recognizing the diverse needs of the market, {Company Name} offers an extensive range of PCB sheets suitable for various applications. The products include single-sided, double-sided, and multi-layered PCBs, accommodating the demanding requirements of industries such as telecommunications, automotive, aerospace, consumer electronics, medical devices, and more.Furthermore, the company specializes in providing customized solutions to meet specific client demands. With a team of experienced technicians and engineers, {Company Name} collaborates closely with clients to develop tailored PCB sheets with precise specifications. This flexibility allows the company to cater to unique requirements and deliver superior products.Quality Assurance and Certifications:{Company Name} recognizes the importance of maintaining consistent quality throughout the production process. Therefore, stringent quality control measures are implemented at every stage, from raw material inspection, manufacturing, to final product testing. The company adheres to international standards such as ISO 9001:2015 and ISO 14001:2015, establishing itself as a trustworthy manufacturer committed to delivering reliable, high-performance PCB sheets.Market Presence and Global Reach:With an unwavering commitment to meeting global demands, {Company Name} has successfully established a strong presence in both domestic and international markets. The company's products are exported to various countries worldwide, gaining recognition for their superior quality and excellent performance. By fostering long-term partnerships and prioritizing customer satisfaction, {Company Name} continues to expand its global reach, contributing to China's reputation as a leading PCB manufacturing hub.Environmental Stewardship and Sustainability:In addition to its focus on product quality, {Company Name} places great emphasis on environmental stewardship. The company implements eco-friendly practices to minimize its environmental footprint, ensuring responsible manufacturing and waste management processes. By embracing sustainability as a core value, {Company Name} sets an example for the industry, contributing to China's efforts towards a greener future.Conclusion:{Company Name}, one of the leading PCB sheet manufacturers in China, embodies excellence, innovation, and continuous improvement. With advanced manufacturing facilities, a wide range of product offerings, customized solutions, and a stringent quality assurance approach, the company has earned a reputable position in the global market. By consistently meeting and exceeding customer expectations, {Company Name} plays a crucial role in further establishing China's dominance in the PCB manufacturing industry.

Top Turnkey Pcb Factories in China: A Comprehensive Guide

China Turnkey PCB Factories Witnessing Growth in Production and QualityIn recent years, China has seen a significant growth in the production and quality of printed circuit boards (PCBs). This growth can be largely attributed to the establishment and expansion of turnkey PCB factories in the country. These factories have played a crucial role in boosting China's position as a leading manufacturer of PCBs on a global scale.One such company that has contributed to this growth is ** (brand name removed). With a history of more than a decade in the PCB manufacturing industry, ** has been a key player in providing turnkey PCB solutions to its customers. The company's state-of-the-art facilities, advanced technology, and commitment to quality have set a high standard for the industry.The market for PCBs has been rapidly expanding, driven by the increasing demand for electronic devices across various industries such as automotive, aerospace, consumer electronics, and telecommunications. This growth has created a need for high-quality PCBs that can meet the requirements of modern electronic applications.In response to this demand, turnkey PCB factories have emerged as a solution for customers looking for a one-stop shop for all their PCB manufacturing needs. These factories offer a comprehensive range of services including PCB design, manufacturing, assembly, and testing. By providing a complete and integrated solution, turnkey PCB factories enable customers to streamline their supply chain and reduce lead times.The growth of turnkey PCB factories in China has also been supported by the government's initiatives to promote the development of the electronics manufacturing industry. This has led to the establishment of industrial parks and special economic zones that provide incentives and support for companies operating in this sector.Furthermore, China's abundant and skilled labor force has contributed to the success of turnkey PCB factories in the country. The availability of skilled workers has enabled these factories to meet the increasing demand for high-quality PCBs, while keeping production costs competitive.In addition to this, the use of advanced technology and automation in PCB manufacturing has been a significant factor in enhancing the quality and efficiency of the production process. Turnkey PCB factories have invested in cutting-edge equipment and processes to ensure that they can meet the stringent requirements of their customers.With the rapid advancements in technology, the demand for more complex and advanced PCBs has also been on the rise. Turnkey PCB factories have been quick to adapt to these changes by investing in research and development to stay ahead of the curve. This has allowed them to offer a wide range of PCB solutions, including multi-layer, flexible, and rigid-flex PCBs, to cater to the diverse needs of their clients.Furthermore, turnkey PCB factories have also been focusing on sustainable and environmentally friendly practices in their manufacturing processes. By employing green initiatives and complying with international standards for environmental protection, these factories have been able to meet the requirements of customers who are increasingly conscious of the environmental impact of their supply chain.Overall, the growth of turnkey PCB factories in China has been a significant development for the electronics manufacturing industry. With their ability to provide a comprehensive and integrated solution for PCB manufacturing, these factories have played a crucial role in meeting the growing demand for high-quality PCBs. Looking ahead, the continued investment in technology, talent, and sustainability is likely to further solidify China's position as a global leader in PCB manufacturing.

4 Layer Flex PCB Factories: Understanding OEM Manufacturing

In the ever-evolving world of technology, the demand for high-performing and innovative printed circuit boards (PCBs) continues to grow. With the rapid advancements in electronic devices and gadgets, the need for flexible and reliable PCBs has become essential for manufacturers. As a response to this demand, OEM 4 Layer Flex PCB Factories have emerged as a leading provider of cutting-edge PCB solutions.With a focus on delivering high-quality and cost-effective PCBs, OEM 4 Layer Flex PCB Factories has established itself as a prominent player in the industry. The company has built a strong reputation for its commitment to innovation, state-of-the-art manufacturing processes, and exceptional customer service. By leveraging a vast network of resources and industry expertise, OEM 4 Layer Flex PCB Factories has become a trusted partner for businesses seeking reliable PCB solutions.One of the key factors that sets OEM 4 Layer Flex PCB Factories apart from its competitors is its specialization in 4-layer flexible PCBs. These PCBs are designed to provide superior performance and reliability, making them ideal for a wide range of applications in industries such as telecommunications, consumer electronics, automotive, and medical devices. The company's expertise in manufacturing 4-layer flexible PCBs has allowed it to stay ahead of the curve and meet the evolving needs of its customers.In addition to its specialization in 4-layer flexible PCBs, OEM 4 Layer Flex PCB Factories prides itself on its state-of-the-art manufacturing facilities. The company utilizes advanced equipment and cutting-edge technologies to produce PCBs that meet the highest quality standards. With a focus on precision and efficiency, OEM 4 Layer Flex PCB Factories is able to deliver a wide range of PCB solutions that are tailored to the specific needs and requirements of its customers.As a customer-centric company, OEM 4 Layer Flex PCB Factories places a strong emphasis on collaboration and communication. The company works closely with its clients to understand their unique challenges and goals, allowing it to develop customized PCB solutions that address their specific needs. By fostering strong relationships with its customers, OEM 4 Layer Flex PCB Factories has earned a reputation for its responsiveness, reliability, and dedication to customer satisfaction.With a commitment to sustainability and environmental responsibility, OEM 4 Layer Flex PCB Factories is also dedicated to implementing eco-friendly manufacturing practices. The company has invested in green technologies and processes to minimize its environmental impact and promote sustainability throughout its operations. By prioritizing environmental stewardship, OEM 4 Layer Flex PCB Factories demonstrates its dedication to both its customers and the planet.Looking ahead, OEM 4 Layer Flex PCB Factories is poised to continue its growth and success in the industry. The company remains focused on innovation and continuous improvement, constantly seeking new ways to enhance its products and services. With a steadfast commitment to quality, reliability, and customer satisfaction, OEM 4 Layer Flex PCB Factories is well-positioned to be a leader in the ever-evolving PCB market for years to come.In conclusion, OEM 4 Layer Flex PCB Factories stands out as a leading provider of high-quality and innovative PCB solutions. With its specialization in 4-layer flexible PCBs, state-of-the-art manufacturing facilities, customer-centric approach, and commitment to sustainability, the company has earned the trust and confidence of its customers. As technology continues to advance, OEM 4 Layer Flex PCB Factories is well-equipped to meet the evolving needs of the industry and deliver exceptional PCB solutions.

High-Quality Power PCB Assembly Factory for OEM Products

OEM Power PCB Assembly Factory Continues to Lead the Industry in Quality and InnovationWith a solid track record of delivering top-notch PCB assembly services, the OEM Power PCB Assembly Factory has firmly established itself as a leader in the industry. The factory, which operates under the umbrella of {}, has been consistently meeting the needs of its clients with high-quality products and cutting-edge technology.Established in {}, the OEM Power PCB Assembly Factory has been providing comprehensive PCB assembly services to a wide range of industries including automotive, telecommunications, consumer electronics, and medical devices. The factory has built a strong reputation for its commitment to quality, precision, and on-time delivery.One of the key factors that sets the OEM Power PCB Assembly Factory apart from its competitors is its commitment to continuous improvement and innovation. The factory is equipped with state-of-the-art machinery and cutting-edge technology, allowing it to stay ahead of the curve in terms of manufacturing processes and product quality. This dedication to innovation has enabled the factory to consistently deliver high-quality PCB assemblies that meet the stringent requirements of its clients.In addition to its focus on innovation, the OEM Power PCB Assembly Factory is also dedicated to maintaining the highest standards of quality control. The factory has implemented rigorous quality control processes at every stage of the production, ensuring that each PCB assembly meets the highest standards of excellence. This dedication to quality has earned the factory numerous certifications and accolades from industry organizations and clients alike.Furthermore, the OEM Power PCB Assembly Factory prides itself on its ability to provide customized solutions to meet the specific needs of its clients. The factory works closely with its clients to understand their unique requirements and develop tailored solutions that address their specific challenges. This personalized approach has earned the factory a loyal customer base and a sterling reputation for exceptional customer service.The OEM Power PCB Assembly Factory also places a strong emphasis on sustainability and environmental responsibility. The factory has implemented green manufacturing practices and prioritizes the use of eco-friendly materials and processes. This commitment to sustainability has not only minimized the factory's environmental impact but has also contributed to cost savings for its clients.Looking ahead, the OEM Power PCB Assembly Factory is committed to maintaining its position as a leader in the industry. The factory continues to invest in research and development to stay at the forefront of technological advancements and market trends. Additionally, the factory is exploring partnerships and collaborations with other industry leaders to further enhance its capabilities and expand its offerings.In conclusion, the OEM Power PCB Assembly Factory has proven itself as a powerhouse in the PCB assembly industry, thanks to its dedication to quality, innovation, and customer satisfaction. As the factory continues to push the boundaries of what is possible in PCB assembly, it is poised to remain a leading force in the industry for years to come.

Enhancing Electronics Production: Unveiling the Process of Board Fabrication

{Board Fabrication} Expands Operations with Cutting-Edge Manufacturing Technology (Board Fabrication) is proud to announce the expansion of its operations with the integration of cutting-edge manufacturing technology. This enhancement to its production capabilities positions the company as a leader in the board fabrication industry, delivering innovative solutions to its diverse clientele.(Board Fabrication) has built a reputation for providing high-quality board fabrication services to a wide range of industries, including telecommunications, automotive, consumer electronics, and aerospace. With its commitment to delivering exceptional products and services, the company has become a trusted partner for businesses globally.To further strengthen its offerings, (Board Fabrication) has invested in state-of-the-art manufacturing technology that enables faster and more precise production processes. The integration of this advanced equipment enhances the company's ability to meet the demands of its discerning clientele with increased efficiency and accuracy.This cutting-edge manufacturing technology is equipped with features such as automated assembly lines, computer-aided design (CAD) software, and advanced robotics. These tools work in synergy to streamline the board fabrication process and optimize the overall production flow. The result is reduced lead times, lower costs, and enhanced overall quality.The new equipment also enables (Board Fabrication) to expand its capabilities in terms of board types and sizes. From single-layer to multi-layer, flexible to rigid, and small to large, the company can now cater to a wider spectrum of custom board fabrication requirements. This versatility strengthens (Board Fabrication)'s market position and allows it to better serve its clients' evolving needs.By integrating automation and robotics, (Board Fabrication) ensures that each step of the manufacturing process is executed with precision. This technology significantly minimizes human errors, leading to improved product quality and reliability. The company's team of experienced engineers and technicians also oversee the production process, incorporating human expertise where needed and ensuring the highest standards are maintained.Additionally, (Board Fabrication) understands the importance of environmental responsibility in today's world. With this in mind, the company has employed eco-friendly practices throughout its manufacturing operations. This commitment to sustainability includes the reduction of waste, the use of energy-efficient machinery, and the implementation of recycling initiatives. (Board Fabrication) remains dedicated to minimizing its environmental footprint while delivering exceptional products.This expansion and incorporation of cutting-edge technology will not only benefit (Board Fabrication)'s existing clients but also attract new ones. By offering improved efficiency, increased capabilities, and enhanced product quality, the company is positioned to be a preferred partner for businesses seeking reliable board fabrication solutions.(Board Fabrication) will continue to invest in research and development to stay at the forefront of technological advancements in the industry. By staying ahead of emerging trends and continuously improving its processes, the company remains a trusted leader in the board fabrication ecosystem.In conclusion, (Board Fabrication) has expanded its operations by integrating cutting-edge manufacturing technology into its processes. With this investment, the company solidifies its position as a leader in the board fabrication industry. The enhanced capabilities, increased efficiency, and commitment to sustainability exemplify (Board Fabrication)'s dedication to delivering outstanding products and services to its valued clients. It is clear that this expansion will pave the way for continued success and growth for (Board Fabrication).

Advanced Technology: Understanding the Benefits of Double PCB in Modern Electronics

[Assistant]Title: Double PCB Revolutionizes Electronics Manufacturing with Cutting-Edge InnovationsIntroduction: In today's dynamic world, the demand for advanced electronic products continues to soar. The evolution of technology requires more efficient and compact circuit boards that can handle complex functionalities. Enter Double PCB, a pioneering company that has revolutionized the electronics manufacturing industry with its cutting-edge solutions. With a rich history of expertise, they are leading the charge in pushing the boundaries of what's possible. This article will delve into the industry wizardry of Double PCB, showcasing how their innovative solutions are transforming the landscape of electronic manufacturing.I. Unveiling Double PCB's Cutting-Edge TechnologiesDouble PCB's proprietary technologies lie at the heart of their revolution. Through immense research and development, the company has introduced numerous breakthroughs that have garnered global recognition. Their technologies encompass two primary areas:1. Double-Sided PCBs:Double PCB's eponymously named double-sided PCB technology stands among their most revolutionary achievements. Unlike traditional single-sided PCBs, double-sided PCBs are designed with two conductive layers on either side of an insulating substrate. This architecture allows for increased circuit density and complexity, resulting in smaller and more reliable electronic products. Double PCB's advanced manufacturing processes and quality assurance measures ensure high-performance double-sided PCBs for a limitless range of applications.2. Multilayer PCBs:Taking innovation to new heights, Double PCB has mastered the art of manufacturing multilayer PCBs. These circuit boards consist of multiple conductive layers, separated by insulating material, and interconnected through vias. By allowing for intricate designs and 3D stacking capabilities, multilayer PCBs enable compact and efficient electronic systems. Double PCB's expertise in this area allows them to create multilayer PCBs of exceptional quality and reliability.II. The Advantages of Double PCB's Cutting-Edge SolutionsDouble PCB's groundbreaking innovations offer numerous advantages to the electronics industry and manufacturers worldwide. Some key benefits are:1. Streamlined Manufacturing Processes:With Double PCB's cutting-edge solutions, manufacturers can optimize their production processes. The advanced technologies reduce the overall number of components, simplify interconnections, and enhance integration capabilities. This streamlining leads to improved manufacturing efficiency, reduced costs, and faster time-to-market for electronic products.2. Enhanced Design Flexibility:Double PCB's double-sided and multilayer PCBs provide engineers with unprecedented design flexibility. The increased circuit density and layer count enable complex and reliable electronic systems in smaller form factors. This flexibility stimulates innovation and empowers engineers to push the boundaries of what is possible.3. Improved Performance and Reliability:Through rigorous testing and quality assurance, Double PCB ensures that their solutions surpass industry standards. The state-of-the-art manufacturing processes, precise material selection, and rigorous quality control measures result in high-performance and reliable circuit boards. This increased reliability reduces system failures, enhances product lifecycles, and improves customer satisfaction.III. Double PCB's Accelerating Market Adoption The impact of Double PCB's innovations is already evident in the electronics manufacturing market. Across diverse sectors such as telecommunications, automotive, aerospace, medical devices, and consumer electronics, companies are increasingly integrating Double PCB's cutting-edge solutions into their products. Their revolutionary technologies have opened up new possibilities for industries that demand compactness, reliability, and optimal performance.IV. Commitment to Sustainable GrowthNot only does Double PCB remain dedicated to technological advancements, but they are also committed to sustainable growth. As part of their corporate social responsibility, the company strives to minimize waste, increase energy efficiency, and reduce their carbon footprint during manufacturing processes. By promoting eco-friendly practices and utilizing recyclable materials, Double PCB actively contributes to a greener future.V. A Promising Future AheadAs the world becomes increasingly digitized and connected, the demand for advanced electronic products will only continue to rise. In this ever-evolving landscape, Double PCB's cutting-edge solutions offer a beacon of innovation and reliability. With their revolutionary double-sided and multilayer PCB technologies, Double PCB is paving the way for smaller, smarter, and more efficient electronic devices, ultimately transforming the electronics manufacturing industry.In conclusion, Double PCB's groundbreaking innovations are at the forefront of the electronics manufacturing revolution. Their advanced double-sided and multilayer PCB technologies provide unparalleled design flexibility, improved performance, and streamlined manufacturing processes. As global adoption of their solutions accelerates, Double PCB's commitment to sustainable growth further solidifies their position as a pioneer in the industry. With a promising future ahead, Double PCB continues to shape the world of electronics, empowering manufacturers to create the advanced products of tomorrow.