How Custom PCBs are Impacting the Electronics Industry

By:Admin

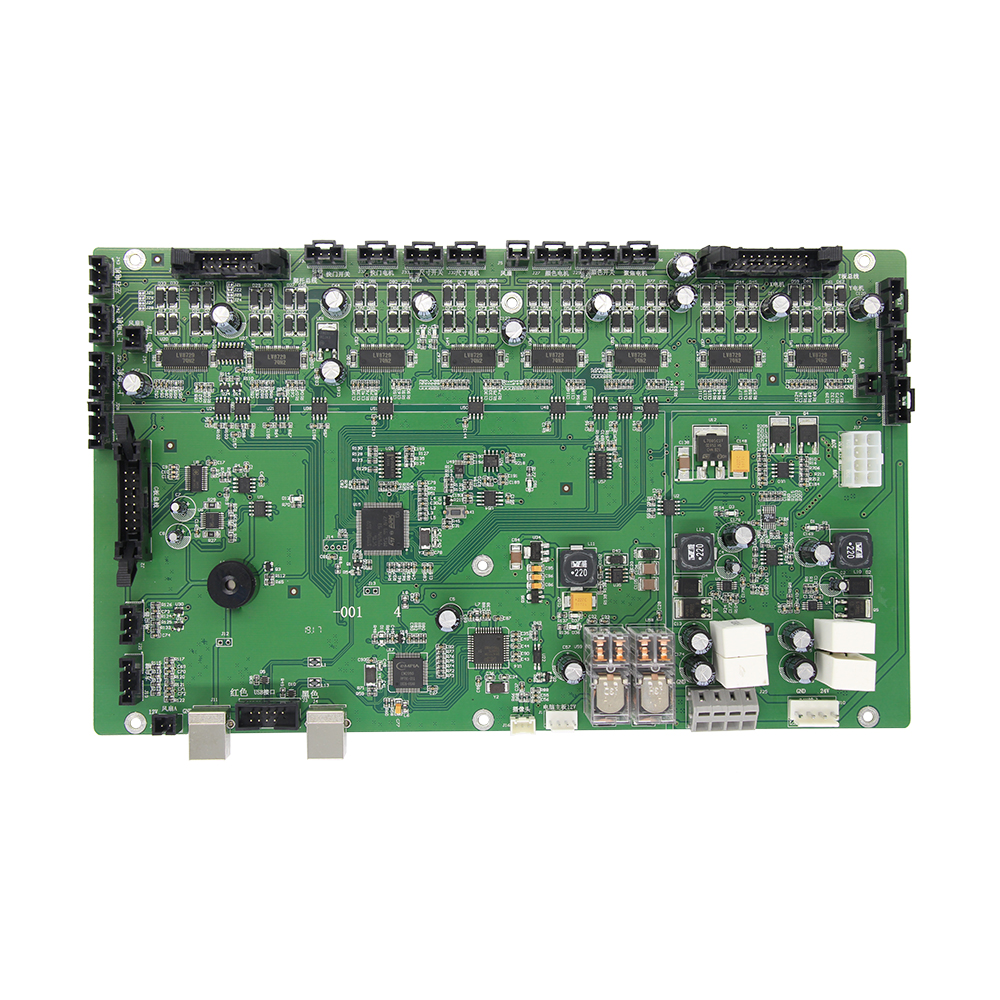

Custom PCB, a leading manufacturer of high-quality printed circuit boards, has announced significant advancements in its production capabilities. The company, known for its commitment to providing customized PCB solutions for a wide range of applications, has made substantial investments in new equipment and technology to further enhance its manufacturing capabilities.

Custom PCB specializes in producing custom circuit boards that meet the unique and specific requirements of its customers. With a focus on quality, reliability, and innovation, the company has built a strong reputation for delivering top-notch PCB solutions to industries such as automotive, aerospace, telecommunications, and consumer electronics.

The recent investments in state-of-the-art equipment have allowed Custom PCB to achieve higher levels of precision and efficiency in its manufacturing processes. By incorporating advanced machinery and automation technologies, the company has significantly improved its production capacity and capability to meet the growing demand for custom PCBs.

"Our ongoing commitment to investing in the latest technologies and equipment has enabled us to elevate our production capabilities to new heights," said the spokesperson for Custom PCB. "We are constantly striving to stay ahead of the curve and provide our customers with the best-in-class PCB solutions that meet the evolving needs of their industries."

In addition to the advancements in equipment, Custom PCB has also expanded its facility to accommodate the growing demand for its services. The company has increased its production area and streamlined its workflow to optimize efficiency and ensure timely delivery of custom PCBs to its customers.

With these enhancements, Custom PCB is well-positioned to continue serving as a trusted partner for businesses seeking reliable, high-quality printed circuit boards. The company's ability to tailor its manufacturing processes to the specific requirements of each customer sets it apart in the industry, allowing for the production of complex, high-performance PCBs that meet the stringent standards of various applications.

As a company that prides itself on its ability to deliver custom solutions, Custom PCB offers a comprehensive range of capabilities, including multilayer PCBs, flexible and rigid-flex PCBs, HDI PCBs, and quick-turn PCB prototyping. Whether it's a small-scale project or a large-scale production run, the company is equipped to handle diverse requirements with precision and expertise.

Custom PCB's commitment to continuous improvement and innovation is underscored by its dedication to maintaining the highest standards of quality and reliability in its products. The company adheres to rigorous quality control processes at every stage of production, ensuring that each custom PCB meets the exact specifications and performance requirements of its intended application.

With its enhanced production capabilities, Custom PCB is poised to meet the increasing demand for custom PCB solutions across various industries. The company's investment in advanced equipment, coupled with its unwavering commitment to delivering top-notch products, reinforces its position as a leading provider of customized printed circuit boards.

As Custom PCB continues to expand its capabilities and strengthen its position in the market, the company remains focused on driving innovation and setting new benchmarks for excellence in the custom PCB manufacturing industry. With a customer-centric approach and a dedication to exceeding expectations, Custom PCB is well-equipped to meet the evolving needs of its customers and deliver unparalleled PCB solutions for a wide range of applications.

Company News & Blog

Top Assembly Manufacturer Reveals Latest Industry Trends

Circuits Assembly Manufacturer, a leading supplier of high-quality electronics manufacturing services, continues to expand its operations and capabilities in order to meet the ever-evolving demands of its customers.With over 20 years of experience in the industry, Circuits Assembly Manufacturer has established a strong reputation for delivering exceptional quality and reliability in its products and services. The company's state-of-the-art manufacturing facilities are equipped with the latest technology and machinery, allowing for efficient and precise production of a wide range of electronic components and assemblies.In line with its commitment to continuous improvement, Circuits Assembly Manufacturer recently announced the expansion of its production capacity to meet the increasing demand for its products. By investing in new equipment and technology, the company aims to streamline its manufacturing processes and enhance its capabilities to take on larger and more complex projects.Furthermore, Circuits Assembly Manufacturer has also been focused on expanding its range of services to offer a comprehensive solution for its customers' electronics manufacturing needs. This includes the addition of advanced testing and inspection capabilities, as well as the introduction of new materials and processes to improve the performance and reliability of its products.In addition to its technical capabilities, Circuits Assembly Manufacturer prides itself on its dedication to customer satisfaction and ongoing support. The company's team of highly skilled engineers and support staff are committed to working closely with clients to understand their specific requirements and provide tailored solutions to meet their needs.Circuits Assembly Manufacturer's dedication to quality and customer service has earned it a loyal customer base and a strong position in the market. The company has established long-term partnerships with leading electronics manufacturers across a range of industries, including automotive, aerospace, telecommunications, and consumer electronics.Furthermore, Circuits Assembly Manufacturer's commitment to sustainability and responsible manufacturing practices sets it apart as a trusted and reliable partner in the industry. The company adheres to strict environmental and ethical standards in its operations, ensuring that its products are not only of the highest quality but also produced in a socially and environmentally responsible manner.As Circuits Assembly Manufacturer continues to grow and expand its capabilities, the company remains dedicated to upholding its core values of quality, reliability, and customer service. By staying at the forefront of technological advancements and industry best practices, Circuits Assembly Manufacturer is well positioned to meet the evolving needs of its customers and continue to be a leading provider of electronics manufacturing services.In conclusion, Circuits Assembly Manufacturer's ongoing commitment to excellence and innovation is evident in its continuous expansion and enhancement of its production capabilities. By investing in new technology and processes, the company is poised to meet the increasing demands of its customers and maintain its position as a trusted and reliable partner in the electronics manufacturing industry. With a strong focus on quality, customer service, and sustainability, Circuits Assembly Manufacturer is well positioned for continued success and growth in the years to come.

High-Quality PCB Printing Service for OEM Needs

OEM PCB Printing Service Expands Offerings to Meet Growing DemandIn response to the increasing demand for high-quality printed circuit boards (PCBs), {Company Name} is pleased to announce an expansion of their OEM PCB printing service. The company, known for their expertise in PCB design and manufacturing, has been a leader in the industry for over a decade.The expansion of the OEM PCB printing service comes as {Company Name} continues to see a surge in demand from clients in various industries, including automotive, aerospace, consumer electronics, and telecommunications. With the growing complexity of electronic devices and the need for more advanced PCBs, {Company Name} has recognized the need to further enhance their capabilities in PCB printing to meet the evolving needs of their customers.{Company Name}’s OEM PCB printing service offers a comprehensive solution for clients seeking high-quality, customized PCBs for their products. With state-of-the-art equipment and a team of experienced technicians, {Company Name} is able to produce PCBs with high precision and reliability, meeting the strictest industry standards.The expansion of the OEM PCB printing service will include the addition of new printing technologies and processes, allowing {Company Name} to offer a wider range of options to their clients. This includes the ability to print PCBs with higher density, finer traces, and more complex designs, catering to the demand for advanced electronic devices with increasingly sophisticated requirements.{Company Name}’s dedication to quality and customer satisfaction is evident in their commitment to investing in the latest printing technologies and equipment. By staying at the forefront of industry advancements, {Company Name} is able to provide their clients with cutting-edge solutions that meet the demands of modern electronic devices and applications.“We are excited to announce the expansion of our OEM PCB printing service, as it reflects our ongoing commitment to meeting the evolving needs of our clients,” said {Spokesperson}, {Title} at {Company Name}. “With the addition of new printing technologies and processes, we are well-positioned to deliver high-quality, customized PCBs that meet the most stringent requirements and specifications.”With the expansion of the OEM PCB printing service, {Company Name} is confident that they will be able to further solidify their position as a leading provider of PCB solutions for clients across various industries. The company’s dedication to innovation and continuous improvement is evident in their ongoing efforts to enhance their capabilities and offer the most advanced PCB printing services available in the market.As the demand for advanced electronic devices continues to grow, {Company Name} remains committed to providing their clients with the most reliable and efficient PCB solutions. By expanding their OEM PCB printing service, {Company Name} is poised to meet the industry’s growing demands and provide their clients with the high-quality PCBs they need to bring their products to market.For more information about {Company Name} and their OEM PCB printing service, please visit {company website} or contact {Contact Person} at {contact email/phone number}.

How to Become a Successful Circuit Board Designer: Tips and Tricks

Circuit Board Designer, a leading company in the field of electronic design and manufacturing, has recently announced groundbreaking innovations in the development of advanced circuit board technology. With a commitment to delivering high-quality and cutting-edge solutions, Circuit Board Designer has continually pushed the boundaries of what is possible in the world of electronics.Founded in 1995, Circuit Board Designer has established itself as a pioneer in the industry, providing a comprehensive range of services including PCB design, layout, and assembly. The company has built a strong reputation for delivering reliable and efficient products, serving a diverse clientele from various sectors such as consumer electronics, automotive, aerospace, and telecommunications.In line with its continuous efforts to revolutionize the electronics industry, Circuit Board Designer has introduced a series of advancements in circuit board design that have set new standards for performance, reliability, and innovation. The company's team of experienced and skilled engineers and designers have worked tirelessly to develop cutting-edge technologies that address the ever-evolving demands of the market.One of the key innovations introduced by Circuit Board Designer is the development of ultra-thin and flexible circuit boards, which have opened up new possibilities for electronic devices in terms of design and functionality. These flexible circuit boards are extremely lightweight and can be bent or twisted without compromising performance, making them ideal for applications in wearable technology, medical devices, and automotive interiors.Furthermore, Circuit Board Designer has also made significant strides in the development of high-speed and high-frequency circuit boards, catering to the growing demand for faster and more efficient electronic devices. By leveraging advanced materials and manufacturing techniques, the company has been able to produce circuit boards capable of handling data transmission at unprecedented speeds, making them ideal for the latest 5G technologies and other high-performance applications.In addition to these technological advancements, Circuit Board Designer has also prioritized sustainability in its manufacturing processes, implementing eco-friendly materials and practices to minimize its environmental impact. The company has embraced the principles of green design and manufacturing, ensuring that its products are not only innovative and reliable but also environmentally responsible.As part of its ongoing commitment to excellence, Circuit Board Designer has invested heavily in research and development, fostering a culture of innovation and collaboration to stay ahead of the curve in a rapidly evolving industry. The company's state-of-the-art facilities and cutting-edge equipment have enabled its team to explore new frontiers in electronic design and manufacturing, driving progress and shaping the future of the industry.Circuit Board Designer's relentless pursuit of excellence and innovation has garnered recognition from industry experts and customers alike, solidifying its position as a trusted and forward-thinking leader in the field of electronic design and manufacturing. With a steadfast dedication to quality and ingenuity, the company continues to push the boundaries of what is possible, shaping the future of electronics and driving progress in the industry.Looking ahead, Circuit Board Designer remains committed to driving innovation and delivering unparalleled solutions to meet the evolving needs of the electronics market. With a focus on advanced technologies, sustainability, and customer satisfaction, the company is well-positioned to lead the way in shaping the future of electronic design and manufacturing, setting new benchmarks for excellence and revolutionizing the industry as a whole.

Top Flex Board PCB Factories in China: A Comprehensive Overview

China Flex Board PCB Factories (Company Name removed), one of the leading manufacturers of flexible printed circuit boards (PCBs) in China, has been making significant strides in the industry. With a focus on high-quality and cutting-edge technology, the company has established itself as a key player in the global PCB market.The company specializes in the design and production of flex and rigid-flex PCBs for a wide range of industries, including automotive, telecommunications, consumer electronics, and medical devices. With state-of-the-art manufacturing facilities and a team of skilled engineers and technicians, China Flex Board PCB Factories has the capability to produce complex and high-density PCBs to meet the demands of its customers.One of the key differentiators of the company is its commitment to innovation and technology. China Flex Board PCB Factories invests heavily in research and development to stay at the forefront of PCB technology. The company has a dedicated team of R&D professionals who are constantly exploring new materials, processes, and design techniques to improve the performance and reliability of its PCBs.In addition to its technical capabilities, China Flex Board PCB Factories places a strong emphasis on quality control and customer satisfaction. The company adheres to stringent quality standards and has implemented rigorous testing procedures to ensure that its products meet the highest levels of performance and reliability. This commitment to quality has earned the trust and loyalty of its customers, many of whom are leading firms in their respective industries.With a strong focus on the global market, China Flex Board PCB Factories has established a robust sales and distribution network to serve customers around the world. The company works closely with its clients to understand their specific requirements and provides tailored solutions to meet their needs. Whether it's a small prototype or a large-scale production run, China Flex Board PCB Factories has the flexibility and capacity to deliver on time and within budget.As part of its growth strategy, the company is continuously expanding its production capacity and investing in the latest manufacturing equipment. By staying ahead of the curve in terms of technology and infrastructure, China Flex Board PCB Factories aims to maintain its competitive edge and drive further growth in the global PCB market.In line with its commitment to sustainability, China Flex Board PCB Factories also prioritizes environmental responsibility in its operations. The company adheres to strict environmental regulations and implements eco-friendly practices throughout its manufacturing processes. This includes the use of recyclable materials, energy-efficient systems, and waste reduction initiatives.Looking ahead, China Flex Board PCB Factories is poised for continued success and expansion in the dynamic PCB industry. With a strong foundation built on innovation, quality, and customer satisfaction, the company is well-positioned to capitalize on the growing demand for high-performance and reliable PCB solutions. As it continues to push the boundaries of technology and manufacturing excellence, China Flex Board PCB Factories is set to maintain its leadership position in the global market.

Top Print Circuit Suppliers in China: A Comprehensive Guide

Chinese Printed Circuit Suppliers on the RiseIn recent years, China has emerged as a major player in the global printed circuit board (PCB) industry. With a growing number of suppliers and manufacturers, China's PCB market is expanding rapidly, which is good news for the electronics industry worldwide. One such company making waves in this space is {}. {} is a leading supplier of printed circuits in China. With a strong focus on innovation and technology, the company has established itself as a reliable and efficient provider of high-quality PCBs. By leveraging cutting-edge manufacturing processes and advanced equipment, {} has built a reputation for delivering top-notch products to its customers.The company's success can be attributed to its commitment to customer satisfaction and continuous improvement. With a customer-centric approach, {} strives to meet the unique requirements of each client, offering custom solutions and personalized services. This has helped {} to build strong and long-lasting relationships with its customers, many of whom are repeat buyers.One of the key advantages of working with {} is its comprehensive range of PCB products. From single-layer boards to multi-layer PCBs, the company offers a diverse portfolio to cater to different applications and industries. Furthermore, {} is capable of producing PCBs in various materials such as FR-4, aluminum, and flexible substrates, providing flexibility and versatility to its customers.In addition to its extensive product range, {} also emphasizes the importance of quality and reliability. The company adheres to strict quality control measures throughout the manufacturing process, ensuring that every PCB that comes out of its facilities meets the highest standards. This dedication to quality has helped {} to earn the trust and confidence of its customers, positioning it as a preferred supplier in the market.Furthermore, {} is committed to sustainable and environmentally friendly practices. The company is aware of the impact of PCB manufacturing on the environment, and as such, it has implemented various measures to minimize its carbon footprint. From using eco-friendly materials to optimizing production processes, {} is dedicated to promoting sustainability in its operations.As China's PCB industry continues to grow, {} is poised to expand its market presence and reach new heights. The company is aware of the global demand for high-quality PCBs, and it is actively seeking opportunities to serve international customers. With a strong emphasis on technological advancement and customer satisfaction, {} is well-equipped to make significant strides in the global PCB market.In conclusion, the rise of Chinese printed circuit suppliers is reshaping the dynamics of the PCB industry. Companies like {} are setting new standards for quality, innovation, and customer service, driving the growth and competitiveness of China's PCB market. As the demand for PCBs continues to surge worldwide, China's role as a leading supplier of printed circuits is only expected to strengthen in the coming years. With its unwavering commitment to excellence, {} is undoubtedly a key player in this transformative industry.

Glass Fiber Material FR-4: Key Information and Uses

FR-4 Glass Fiber Material: A Game-Changer in the Manufacturing IndustryIn today’s fast-paced and ever-evolving manufacturing industry, companies are constantly seeking new and innovative materials to enhance the performance and reliability of their products. One such material that has been gaining significant attention in recent years is FR-4 glass fiber material. Known for its exceptional strength, durability, and electrical properties, FR-4 has become a game-changer in the manufacturing industry, revolutionizing the way products are designed and produced.FR-4 glass fiber material is a type of composite material that is made from woven glass fabric and epoxy resin. This combination results in a highly versatile material that is suitable for a wide range of applications, including printed circuit boards, electrical insulation, and structural components. One of the key advantages of FR-4 is its high mechanical strength and resistance to heat and moisture, making it an ideal choice for demanding applications in the automotive, aerospace, and electronics industries.With its excellent electrical insulating properties, FR-4 has become the material of choice for printed circuit boards (PCBs), which are essential components in electronic devices and systems. The ability of FR-4 to provide reliable insulation and support for electronic components has made it a staple in the design and production of PCBs, allowing manufacturers to create high-performance and durable electronic products.In addition to its electrical properties, FR-4 also offers exceptional thermal performance, making it suitable for use in applications where heat dissipation is a critical factor. This capability has been particularly valuable in the automotive and aerospace industries, where FR-4 is used to create lightweight and heat-resistant components that can withstand the demanding conditions of these environments.Furthermore, FR-4’s high mechanical strength and dimensional stability have made it a preferred material for structural components in various industries. Its ability to withstand high levels of stress and strain, as well as its resistance to corrosion and chemicals, has made FR-4 a go-to material for applications such as equipment enclosures, housing for machinery, and structural supports.With the demand for high-performance and durable materials on the rise, the market for FR-4 glass fiber material has experienced substantial growth in recent years. Manufacturers have recognized the value of using FR-4 in their products, and as a result, the material has become more widely available and cost-effective.One company that has been at the forefront of developing and utilizing FR-4 glass fiber material is {}. Founded in {}, the company has established itself as a leading provider of high-quality FR-4 products for a wide range of industrial applications. With a strong focus on research and development, the company has continuously advanced the properties and performance of FR-4, ensuring that its products meet the highest standards of quality and reliability.For over {} years, {} has been a trusted partner for manufacturers seeking to leverage the benefits of FR-4 in their products. The company’s extensive range of FR-4 materials, including sheets, laminates, and composites, have been widely adopted in industries such as electronics, telecommunications, automotive, and aerospace, where the demand for high-performance materials is paramount.Through its commitment to innovation and customer satisfaction, {} has positioned itself as a leader in the FR-4 glass fiber material market, providing manufacturers with the tools they need to create cutting-edge products that meet the demands of today’s competitive market. With a strong emphasis on quality, reliability, and performance, {} continues to drive the advancement of FR-4 glass fiber material, setting new standards for the manufacturing industry.As the manufacturing industry continues to evolve, the role of high-performance materials like FR-4 glass fiber material will only become more significant. With its exceptional properties and versatility, FR-4 has proven to be a game-changer in the way products are designed and manufactured, offering manufacturers a competitive edge in a rapidly changing market. As companies like {} continue to push the boundaries of what is possible with FR-4, the future of manufacturing looks brighter than ever.

4 Layer Flex PCB Factories: Understanding OEM Manufacturing

In the ever-evolving world of technology, the demand for high-performing and innovative printed circuit boards (PCBs) continues to grow. With the rapid advancements in electronic devices and gadgets, the need for flexible and reliable PCBs has become essential for manufacturers. As a response to this demand, OEM 4 Layer Flex PCB Factories have emerged as a leading provider of cutting-edge PCB solutions.With a focus on delivering high-quality and cost-effective PCBs, OEM 4 Layer Flex PCB Factories has established itself as a prominent player in the industry. The company has built a strong reputation for its commitment to innovation, state-of-the-art manufacturing processes, and exceptional customer service. By leveraging a vast network of resources and industry expertise, OEM 4 Layer Flex PCB Factories has become a trusted partner for businesses seeking reliable PCB solutions.One of the key factors that sets OEM 4 Layer Flex PCB Factories apart from its competitors is its specialization in 4-layer flexible PCBs. These PCBs are designed to provide superior performance and reliability, making them ideal for a wide range of applications in industries such as telecommunications, consumer electronics, automotive, and medical devices. The company's expertise in manufacturing 4-layer flexible PCBs has allowed it to stay ahead of the curve and meet the evolving needs of its customers.In addition to its specialization in 4-layer flexible PCBs, OEM 4 Layer Flex PCB Factories prides itself on its state-of-the-art manufacturing facilities. The company utilizes advanced equipment and cutting-edge technologies to produce PCBs that meet the highest quality standards. With a focus on precision and efficiency, OEM 4 Layer Flex PCB Factories is able to deliver a wide range of PCB solutions that are tailored to the specific needs and requirements of its customers.As a customer-centric company, OEM 4 Layer Flex PCB Factories places a strong emphasis on collaboration and communication. The company works closely with its clients to understand their unique challenges and goals, allowing it to develop customized PCB solutions that address their specific needs. By fostering strong relationships with its customers, OEM 4 Layer Flex PCB Factories has earned a reputation for its responsiveness, reliability, and dedication to customer satisfaction.With a commitment to sustainability and environmental responsibility, OEM 4 Layer Flex PCB Factories is also dedicated to implementing eco-friendly manufacturing practices. The company has invested in green technologies and processes to minimize its environmental impact and promote sustainability throughout its operations. By prioritizing environmental stewardship, OEM 4 Layer Flex PCB Factories demonstrates its dedication to both its customers and the planet.Looking ahead, OEM 4 Layer Flex PCB Factories is poised to continue its growth and success in the industry. The company remains focused on innovation and continuous improvement, constantly seeking new ways to enhance its products and services. With a steadfast commitment to quality, reliability, and customer satisfaction, OEM 4 Layer Flex PCB Factories is well-positioned to be a leader in the ever-evolving PCB market for years to come.In conclusion, OEM 4 Layer Flex PCB Factories stands out as a leading provider of high-quality and innovative PCB solutions. With its specialization in 4-layer flexible PCBs, state-of-the-art manufacturing facilities, customer-centric approach, and commitment to sustainability, the company has earned the trust and confidence of its customers. As technology continues to advance, OEM 4 Layer Flex PCB Factories is well-equipped to meet the evolving needs of the industry and deliver exceptional PCB solutions.

How to Choose the Best PCB at the Right Price

Price Pcb, a leading manufacturer of high-quality printed circuit boards, has recently announced a significant price reduction on their products. This move comes as part of the company's ongoing efforts to provide more affordable and accessible solutions for customers in the electronics industry.Price Pcb has been in the business of manufacturing high-quality PCBs for over a decade, and their commitment to excellence and customer satisfaction has made them a trusted name in the industry. With a state-of-the-art manufacturing facility and a team of highly skilled professionals, the company is able to produce a wide range of PCBs to meet the diverse needs of their customers.The recent price reduction is a strategic decision aimed at making Price Pcb's products more competitive in the market. By lowering the cost of their PCBs, the company hopes to attract new customers and retain existing ones, while also providing more value for money. This move is also in line with Price Pcb's mission to make high-quality PCBs more accessible to a wider range of customers, including startups, small businesses, and hobbyists.In a statement, the company's CEO expressed his excitement about the price reduction, stating that "We are constantly seeking ways to improve our products and services, and this price reduction is a testament to our dedication to customer satisfaction. We believe that by making our high-quality PCBs more affordable, we can better serve our customers and help them achieve their goals."The price reduction applies to all of Price Pcb's products, including single-sided, double-sided, and multi-layer PCBs. Customers can now expect to enjoy significant savings on their orders, without compromising on quality or performance. This is especially beneficial for small businesses and startups that may have budget constraints but still require top-notch PCBs for their electronic products.Price Pcb's decision to reduce prices also reflects the company's confidence in its ability to streamline the manufacturing process and optimize production costs, without sacrificing quality. By leveraging their advanced manufacturing techniques and cutting-edge technology, the company is able to pass on the savings to their customers, while maintaining the highest standards of excellence.This move is expected to have a positive impact on the electronics industry, as more companies and individuals will now have access to high-quality PCBs at a more affordable price point. This, in turn, is likely to stimulate innovation and creativity, as customers will be able to explore new ideas and projects with the assurance of reliable and cost-effective PCB solutions from Price Pcb.Overall, the recent price reduction by Price Pcb is a testament to the company's commitment to customer satisfaction and its determination to lead the way in providing high-quality, affordable PCBs to the electronics industry. With this move, Price Pcb is poised to further solidify its position as a trusted partner for customers seeking top-notch PCB solutions for their electronic products.

Top PCBA Circuit Board Supplier in the Market: A Complete Guide

Pcba Circuit Board Supplier is a leading provider of high-quality printed circuit board assemblies (PCBAs) for various industries including telecommunications, automotive, medical, and consumer electronics. With over 20 years of experience in the industry, they have established a reputation for delivering reliable and innovative circuit board solutions to their customers.The company specializes in providing custom-designed PCBAs that meet the unique requirements of their clients. Their team of experienced engineers and technicians work closely with customers to understand their specific needs and then design and develop PCBAs that meet these requirements. This level of customization allows PcbA Circuit Board Supplier to offer a wide range of PCBAs that are tailored to the exact specifications of each customer, ensuring the highest levels of performance and reliability.In addition to custom PCBAs, the company also offers a range of standard PCBAs that are suitable for a variety of applications. These standard PCBAs are designed to meet industry-specific standards and regulations while still providing the high-quality performance that PcbA Circuit Board Supplier is known for.One of the key differentiators for PcbA Circuit Board Supplier is their commitment to quality and reliability. The company utilizes state-of-the-art manufacturing processes and equipment to ensure that each PCBA meets the highest standards for performance and durability. Additionally, they have implemented rigorous quality control measures at each stage of the manufacturing process to identify and address any potential issues before the final product is delivered to the customer.Furthermore, PcbA Circuit Board Supplier is dedicated to staying at the forefront of technological advancements in the PCB industry. They continually invest in research and development to explore new materials, processes, and design techniques that can further improve the performance and reliability of their PCBAs. By staying ahead of the curve, PcbA Circuit Board Supplier can offer their customers the latest and most advanced PCBAs on the market.The company's commitment to customer satisfaction is evident in their strong emphasis on customer service. From the initial consultation to post-delivery support, PcbA Circuit Board Supplier's team is dedicated to providing the highest level of customer service to ensure that their clients' needs are met every step of the way.PcbA Circuit Board Supplier takes great pride in their ability to deliver high-quality PCBAs that meet the diverse needs of their customers. With their expertise, commitment to quality, and dedication to customer satisfaction, they have established themselves as a trusted and reliable partner for businesses looking for top-of-the-line PCBAs.In conclusion, PcbA Circuit Board Supplier is a leading provider of custom and standard PCBAs for a wide range of industries. With their focus on quality, reliability, and customer satisfaction, they continue to be a top choice for businesses looking for high-performance circuit board solutions. As they continue to invest in research and development, their commitment to innovation ensures that they will remain at the forefront of the PCB industry for years to come.

Top Tips for PCBA Assembly with Surface Mount Technology

PCBA SMT, a leading provider of electronic manufacturing services, has recently announced a major expansion of its capabilities to meet the growing demand for high-quality printed circuit board assemblies (PCBAs). With a focus on advanced SMT (Surface Mount Technology) solutions, the company is poised to deliver cutting-edge PCBAs for a wide range of industries, including aerospace, automotive, telecommunications, and consumer electronics.The expansion comes at a time when the global electronics industry is experiencing rapid growth, driven by technological advancements and increasing consumer demand for innovative electronic devices. As a result, there is a growing need for PCBAs that are not only reliable and efficient but also compact and cost-effective. PCBA SMT is well-positioned to address these requirements, thanks to its state-of-the-art manufacturing facilities and extensive experience in the field.The company's advanced SMT capabilities enable the placement of electronic components directly onto the surface of the PCB, resulting in smaller, lighter, and more efficient PCBAs. By leveraging the latest equipment and technologies, PCBA SMT is able to achieve high levels of precision and accuracy in component placement, ensuring the overall quality and performance of the final assembly.In addition to its SMT capabilities, PCBA SMT also offers a comprehensive range of services, including PCB design, prototyping, testing, and assembly. This end-to-end approach allows the company to provide customised solutions that meet the unique needs of each customer, from small startups to multinational corporations.With a strong focus on quality and reliability, PCBA SMT adheres to strict quality control standards throughout the manufacturing process. This includes rigorous testing and inspection procedures to ensure that every PCBA meets the highest standards of performance and durability. As a result, customers can rely on PCBA SMT to deliver products that meet their exact specifications and performance requirements.Furthermore, the company is committed to sustainability and environmental responsibility in its manufacturing processes. PCBA SMT has implemented various initiatives to minimise waste, reduce energy consumption, and recycle materials, in line with its commitment to eco-friendly practices.The expansion of PCBA SMT's capabilities comes as part of the company's ongoing commitment to innovation and customer satisfaction. By investing in the latest technologies and expanding its manufacturing capabilities, PCBA SMT aims to further solidify its position as a leading provider of electronic manufacturing services.In light of the expansion, PCBA SMT is also looking to expand its market presence and reach new customers both domestically and internationally. The company is actively seeking partnerships and collaborations with businesses seeking high-quality PCBAs for their products. Through these efforts, PCBA SMT aims to contribute to the success and growth of its customers, while further establishing itself as a trusted and reliable partner in the electronics industry.Overall, the expansion of PCBA SMT's capabilities is a significant development that highlights the company's dedication to meeting the evolving needs of the electronics industry. With its advanced SMT solutions and commitment to quality, PCBA SMT is well-positioned to drive innovation and deliver superior electronic manufacturing services to a diverse range of customers.